In industries and processes where precise control and management of fluids are critical, the choice of reliable equipment is of utmost importance. Manifolds play a crucial role in regulating fluid flow and are widely used in various applications ranging from oil and gas to pharmaceuticals and food processing. One such reliable and robust solution is a Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve.

Stainless steel manifolds are increasingly becoming the preferred choice in industries where hygiene, durability, and corrosion resistance are essential. Stainless steel is well-known for its excellent mechanical properties, including high tensile and yield strength, making it ideal for demanding applications. Moreover, it offers superior resistance to rust and chemicals, ensuring a longer lifespan and reduced maintenance costs.

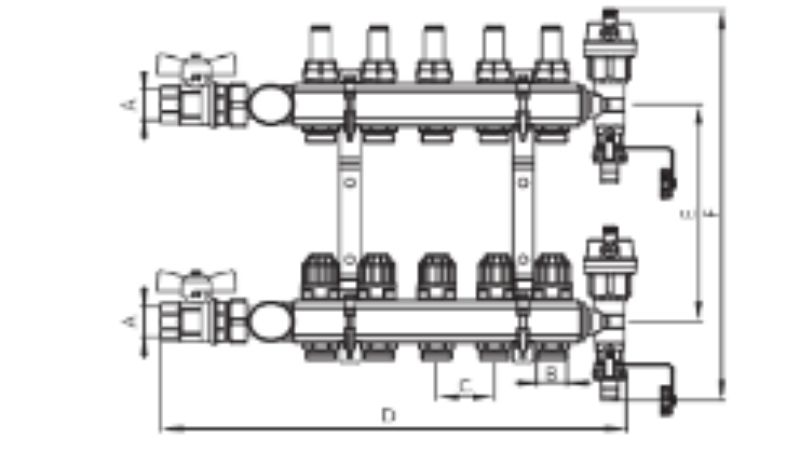

The inclusion of a flow meter in the stainless steel manifold provides operators with accurate and real-time information about the fluid flow rates. This data is crucial in monitoring and controlling the flow to ensure optimal performance and prevent any potential disruptions or inefficiencies. The flow meter can be integrated directly into the manifold, allowing for a compact and space-saving solution.

The ball valve is another essential component of the stainless steel manifold, enabling precise control and shut-off of fluid flow. Ball valves are known for their reliability, high flow capacity, and low-pressure drop characteristics. Their smooth operation and tight sealing ensure minimal leakage, reducing the risk of process contamination and optimizing system performance.

The drain valve featured in the stainless steel manifold allows for effective drainage of the system during maintenance or shutdowns. It facilitates the removal of unwanted fluids, debris, or sediments, ensuring the smooth operation and longevity of the entire system. The drain valve can be easily accessed and operated, providing efficient and convenient maintenance procedures.

One of the primary advantages of using a Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve, is its versatility and compatibility with a wide range of fluids. Stainless steel is resistant to corrosion from various substances, including acids, alkalis, and solvents, making it suitable for applications involving harsh chemicals. This versatility ensures that the manifold can be used in diverse industries such as petrochemical, pharmaceutical, food and beverage, and water treatment.

Furthermore, stainless steel manifolds are designed to meet strict industry standards and regulations, ensuring the highest level of performance and safety. These standards include pressure ratings, temperature limits, and material compatibility requirements. Manufacturers of stainless steel manifolds adhere to these regulations, providing customers with reliable and compliant solutions for their fluid control needs.

Maintenance and longevity are crucial factors to consider in any equipment. Stainless steel manifolds require minimal maintenance due to their inherent corrosion resistance and durability. They can withstand harsh environments, extreme temperatures, and frequent usage without compromising their performance. This reduces downtime, enhances productivity, and contributes to a cost-effective solution.

In conclusion, Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve offer reliable performance, durability, and versatility in fluid control applications. Their corrosion resistance, mechanical properties, and compliance with industry standards make them the ideal choice for industries that prioritize safety, hygiene, and efficiency. Investing in a high-quality stainless steel manifold ensures long-term reliability and enhanced performance, ultimately leading to improved productivity and cost savings.

Post time: Oct-25-2023