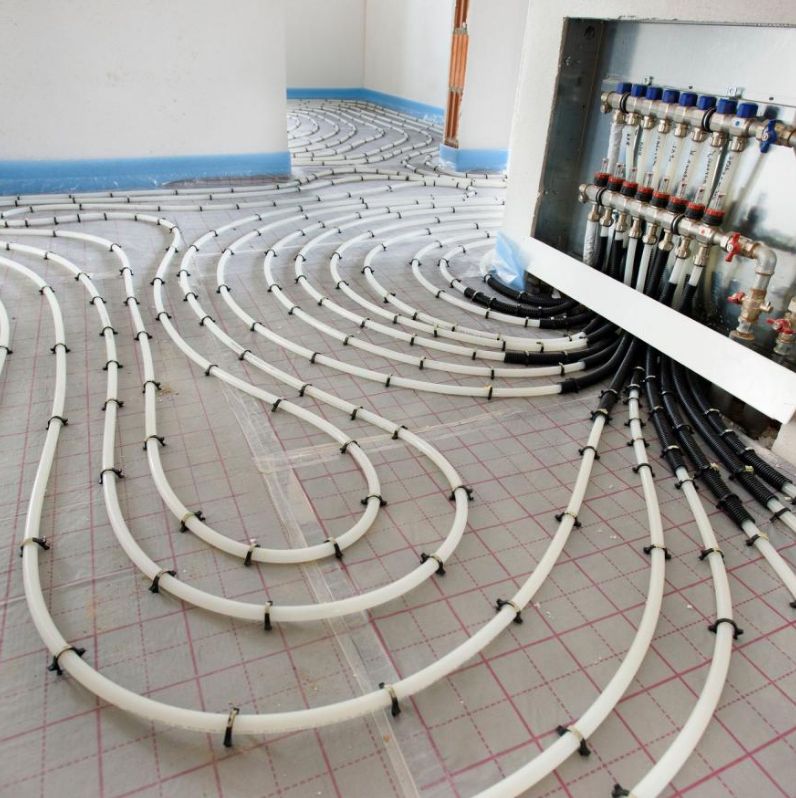

A stainless steel manifold is a crucial component in various industrial applications. It acts as a distribution system, allowing the control and regulation of fluid flow in a network of pipes or tubing. When it comes to choosing the right Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve, including the inclusion of essential features such as a flow meter, ball valve, and drain valve. These features play vital roles in optimal system performance, maintenance, and safety.

Flow Meter:

A flow meter is an instrument used to measure the rate of fluid flow within a system. In the case of a stainless steel manifold, a flow meter allows for accurate monitoring and control of fluid flow rates. This is particularly important in industries such as oil and gas, chemical manufacturing, and water treatment, where precise flow measurement is critical for process efficiency and cost control.

When selecting a stainless steel manifold with a flow meter, it is essential to consider the type and accuracy of the flow meter. Common types of flow meters used in industrial applications include electromagnetic, ultrasonic, and differential pressure meters. Each type has its own advantages and limitations, so it is crucial to choose the flow meter that best suits the specific application requirements.

Ball Valve:

A ball valve is a type of valve that uses a rotating ball to control the flow of fluid. It offers a reliable and efficient means of opening, closing, or regulating the flow within a stainless steel manifold. Ball valves are essential components of manifold systems as they provide an easy and convenient way to isolate or redirect the flow of fluid through the network.

When selecting a Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve, it is important to consider factors such as the valve material, size, and pressure rating. Stainless steel ball valves are highly recommended for industrial applications due to their excellent corrosion resistance and durability. Additionally, the size and pressure rating of the ball valve should be chosen based on the specific flow requirements and operating conditions of the system.

Drain Valve:

A drain valve is a small valve used to release fluid or gas from a system. In the case of a stainless steel manifold, a drain valve is essential for system maintenance, flushing, or draining excess fluids. It allows for the removal of contaminants, debris, or stagnant fluid that may accumulate within the manifold over time.

When selecting a Stainless Steel Manifold With Flow Meter Ball Valve And Drain Valve, it is important to consider factors such as the valve size, type, and ease of operation. The valve should be adequately sized to allow for efficient draining without causing excessive flow restrictions. Additionally, a valve with a convenient operating mechanism, such as a lever or quarter-turn handle, can greatly simplify maintenance and ensure safety during drain operations.

In conclusion, choosing the right stainless steel manifold with essential features such as a flow meter, ball valve, and drain valve is crucial for optimal system performance, maintenance, and safety. Each feature plays a specific role in controlling fluid flow, regulating pressure, and facilitating maintenance operations. When selecting these components, factors such as accuracy, material compatibility, and ease of operation should be carefully considered to ensure long-lasting and efficient manifold functionality.

Post time: Oct-13-2023