Short Lead Time for Four Parts Mixing Valve - Mixing water system /The water mixing center – Xinfan

Short Lead Time for Four Parts Mixing Valve - Mixing water system /The water mixing center – Xinfan Detail:

| Warranty: | 2 Years | After-sale Service: | Online technical support |

| Application: | Apartment | Design Style: | Modern |

| Place of Origin: | Zhejiang, China | Brand Name: | SUNFLY |

| Type: | Floor Heating Systems | Keywords: | Brass Water Mixing System |

| Color: | Nickel plated | Size: | 1″ |

| MOQ: | 5 sets | Name: | Water Mixing system |

| Model Number | XF15231 | ||

| Brass Project Solution Capability | graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

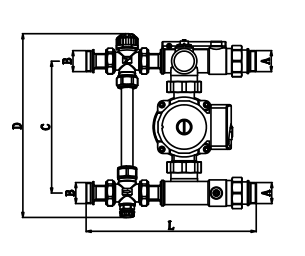

Product parameters

|

Specifications SIZE: |

| 1” |

|

A: 1’’ |

|

B: 1’’ |

|

|

C: 210 |

|

|

D: 287 |

|

|

L: 267 |

Product material

Brass Hpb57-3(Accepting other copper materials with customer-specified, such as Hpb58-2,Hpb59-1,CW617N,CW603N and so on)

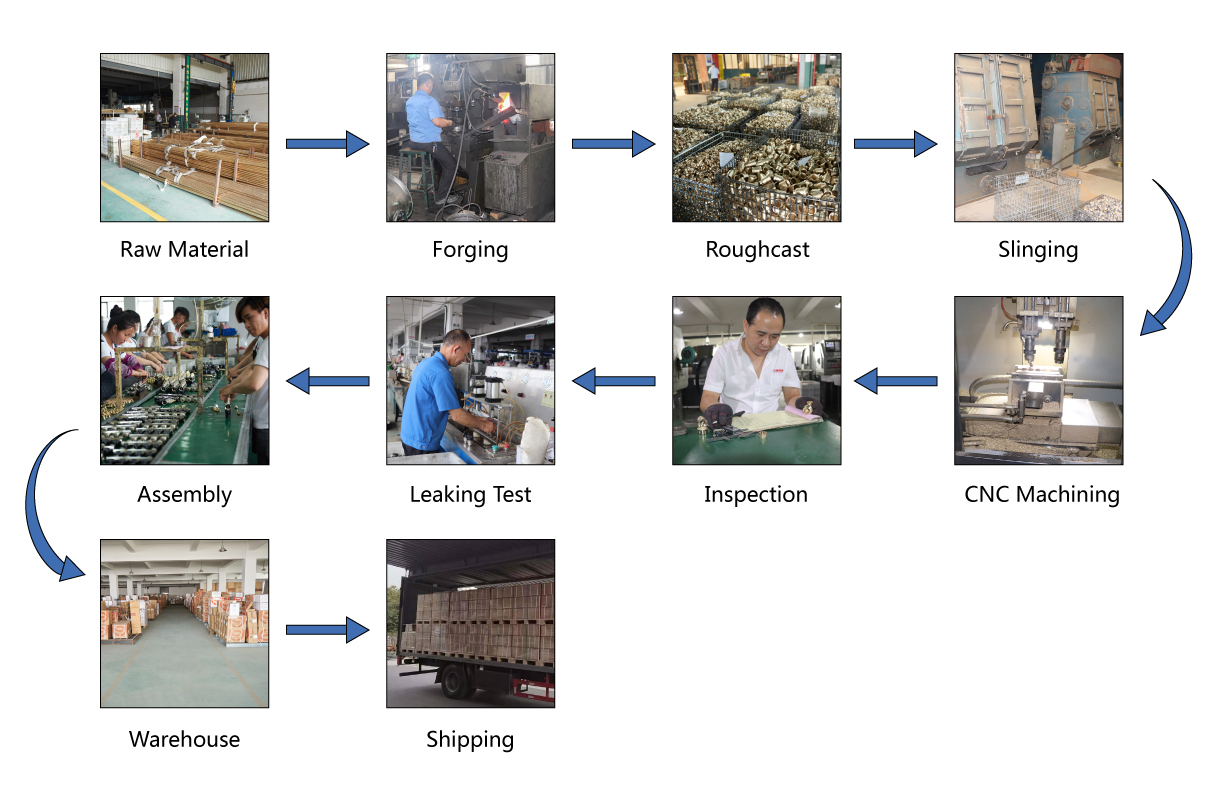

Processing Steps

From raw material to finished product,process by Raw material,forging,roughcast, slingling,CNC machining,inspection,leaking test,assembly, finally packing and warehouse,shipping.

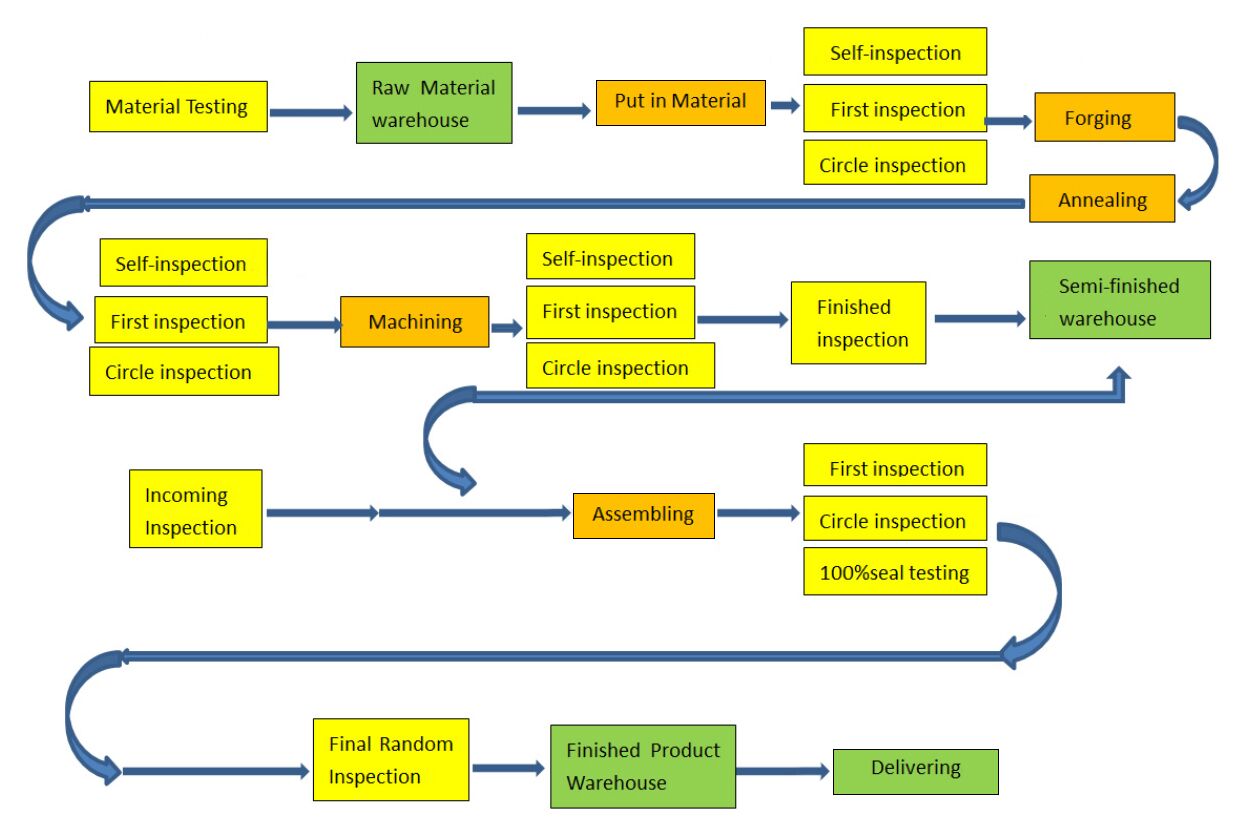

Material Testing, Raw Material Warehouse, Put In Material, Self-Inspection, First Inspection, Circle Inspection, Forging, Annealing, Self-Inspection, First Inspection, Circle Inspection, Machining, Self-Inspection, First Inspection, Circle Inspection, Finished Inspection, Semi-Finished Warehouse, Assembling, First Inspection, Circle Inspection, 100% Seal Testing, Final Random Inspection, Finished Product Warehouse, Delivering

Applications

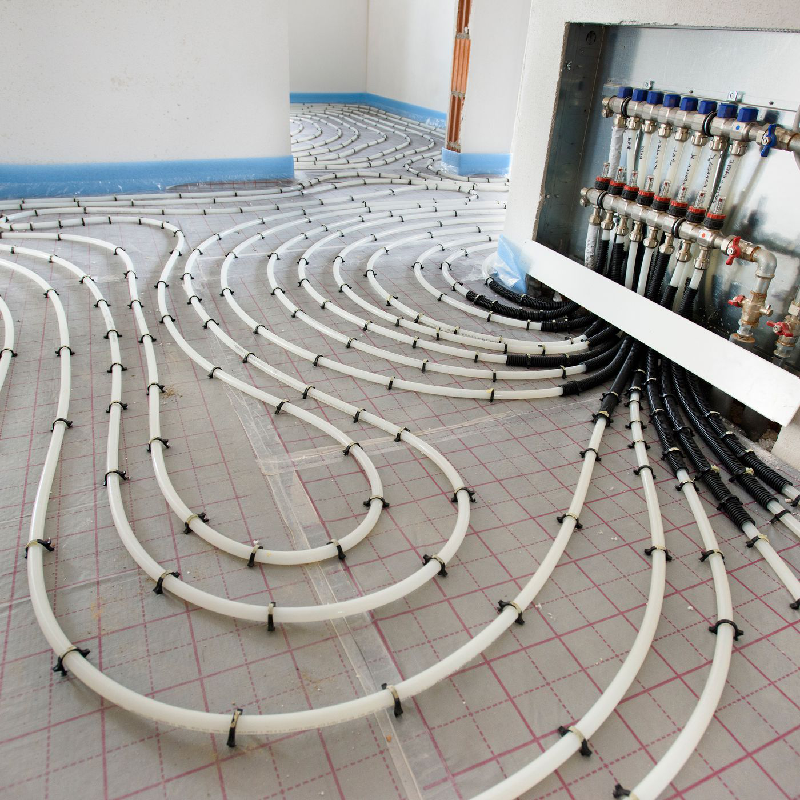

Hot or cold water, manifold for floor heating, heating system, mix water system, construction materials etc.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

The water mixing center is a water temperature and flow control system composed of a circulating water pump, an electric regulating valve, a ball valve with a thermometer, a controller, a temperature sensor, a filter valve, and a sub-catchment device.

The role of mixing center

The water mixing center adjusts the temperature of the high-temperature water provided by the wall-hung boiler through a thermostat and a regulating valve, and converts it into low-temperature water required for floor heating.

While adjusting the water temperature, the circulation pump can also be used to adjust the flow rate to improve the overall comfort of the floor heating.

In addition to these two main functions, the water mixing center also has functions such as reducing the temperature fluctuation of the outlet water of the wall-hung boiler.

Considering the safety and comfort of floor heating, the floor heating water temperature required by the national standard is not more than 60℃, and the suitable temperature is 35℃~45℃.

If the water outlet temperature of the wall-hung boiler is set at 45°C, it will be in a low-load operation state, and the thermal efficiency will often be lower than the optimal value, which also brings two problems:

1. The low temperature operation of the wall-hung boiler is likely to cause frequent start and stop of the equipment, which will increase the energy consumption and affect the service life of the wall-hung boiler.

2. Insufficient combustion of gas aggravates the carbon deposit of wall-hung boilers, which affects the normal use of wall-hung boilers for a long time.

PS: If it is a condensing furnace suitable for low-temperature operation, the above problems will not occur.

The installation of the water mixing center allows the wall-hung boiler heat source and the floor heating terminal to work in their respective suitable working conditions at the same time, which improves the efficiency of the system and reduces the frequent start and stop of the wall-hung boiler to a certain extent.

Secondly, the water mixing center will provide accurate water temperature and flow according to the needs of the room. While improving comfort, it also reduces energy consumption to a certain extent.

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Short Lead Time for Four Parts Mixing Valve - Mixing water system /The water mixing center – Xinfan , The product will supply to all over the world, such as: Israel, Accra, Brazil, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!