Brass temperature control valve

| Warranty: | 2 Years | Model Number: | XF50002/XF60609G |

| Post-sale Service: | Online technical support | Type: | Floor Heating Systems |

| Place of Origin: | Zhejiang, China, | Keywords: | Temperature control valve |

| Brand Name: | SUNFLY | Color: | Nickel plated |

| Application: | Apartment | Size: | 1/2” 3/4”1” |

| Design Style: | Modern | MOQ: | 1000 |

| Name: | Solution Brass temperature control valve Brass Project | ||

| Capability: | Graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

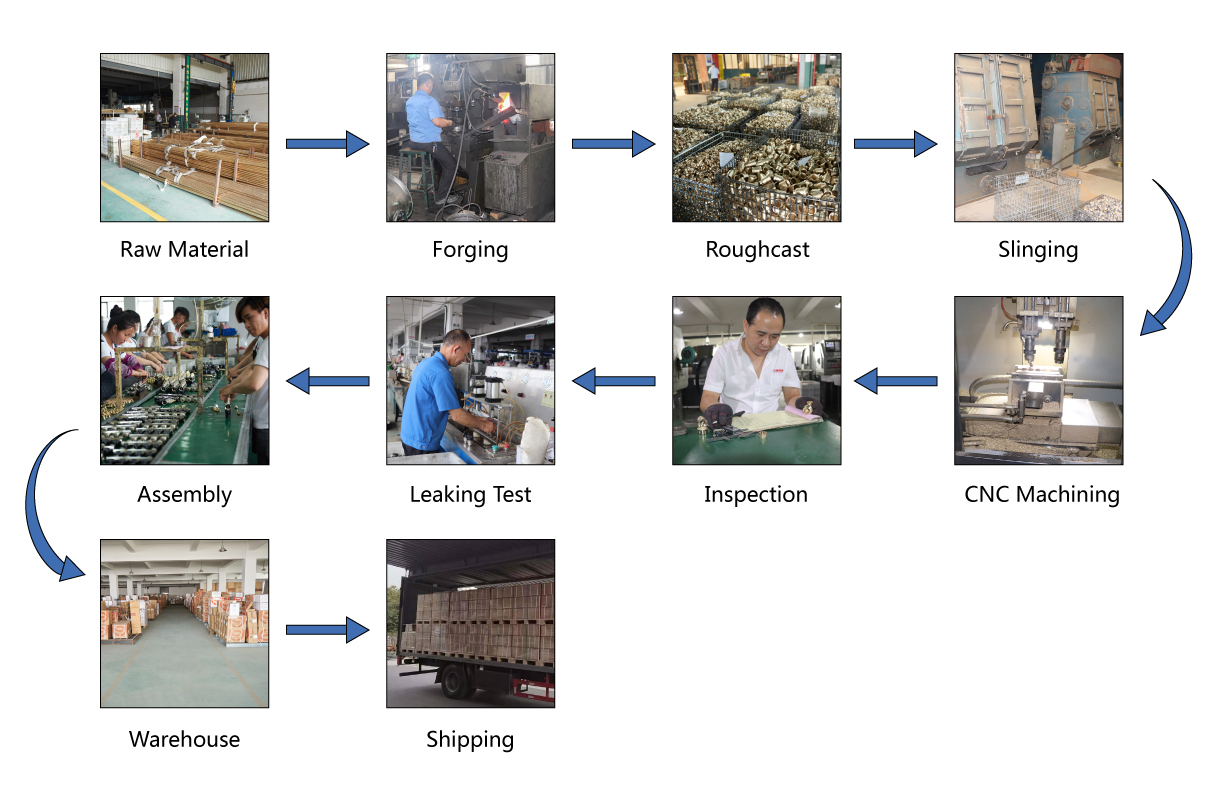

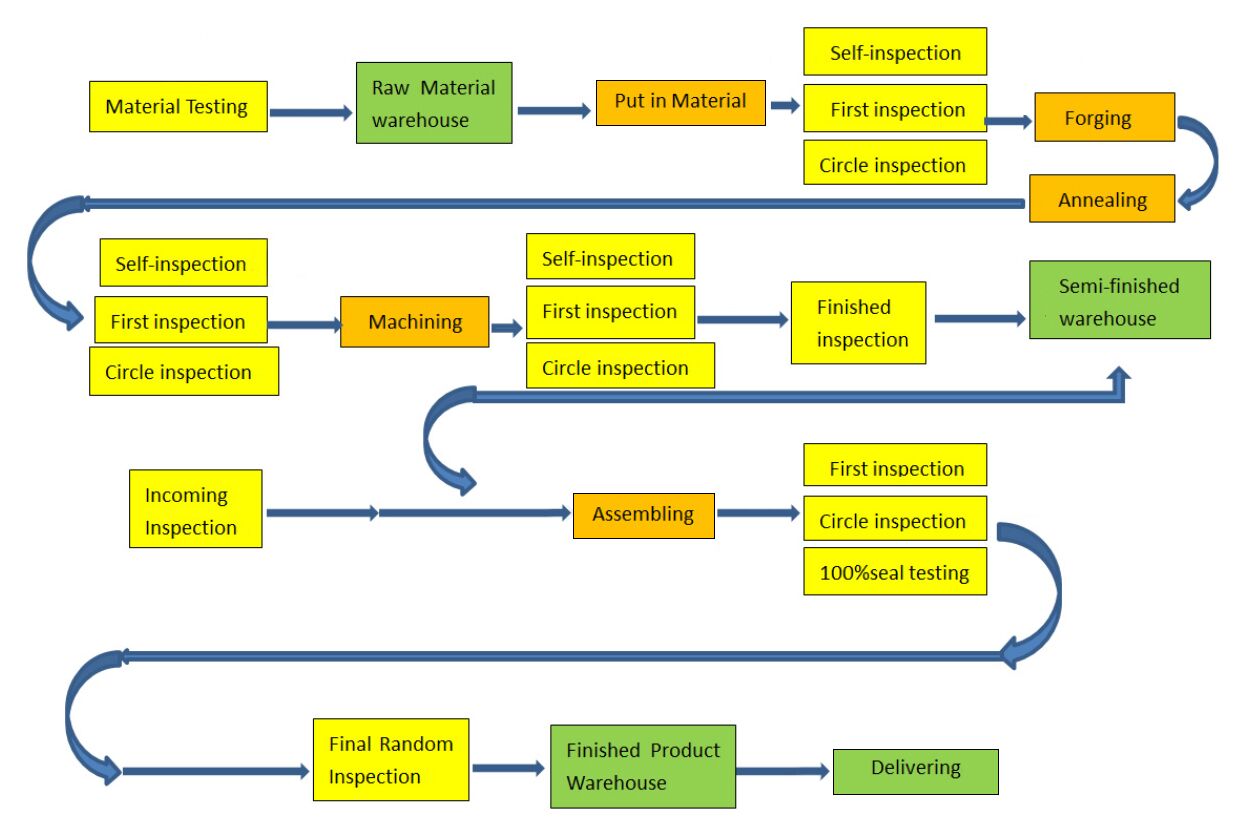

Processing Steps

Raw Material, Forging, Roughcast, Slinging, CNC Machining, Inspection, Leaking Test, Assembly, Warehouse, Shipping

Material Testing, Raw Material Warehouse, Put In Material, Self-Inspection, First Inspection, Circle Inspection, Forging, Annealing, Self-Inspection, First Inspection, Circle Inspection, Machining, Self-Inspection, First Inspection, Circle Inspection, Finished Inspection, Semi-Finished Warehouse, Assembling, First Inspection, Circle Inspection, 100% Seal Testing, Final Random Inspection, Finished Product Warehouse, Delivering

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

Working principle:

Temperature control Valves are used for the end of heating and air conditioning systems to switch flow.The temperature control valve can automatically maintain the indoor

temperature of its installation area according to the setting of the constant temperature controller.

This series of temperature control valve joints hydraulic seal innovation,and the radiator can connection without using other sealing materials,loose joint on the rubber seal can guarantee fast, reliable, multiple installation.Thermostatic controller with actual temperature display panel for easy adjustment.

Structure feature

Body

The stem is made of stainless steel and double imported Italian EPDM material 'O' ring seal. This type of seal ensures that the valve stem operates100,000 times without any dripping.

The special shape of the piston optimizes the hydraulic characteristics of the Temperature control valve when it is switched, reducing noise and high flow rates. The large path between the seat and the piston guarantees a lower pressure loss.