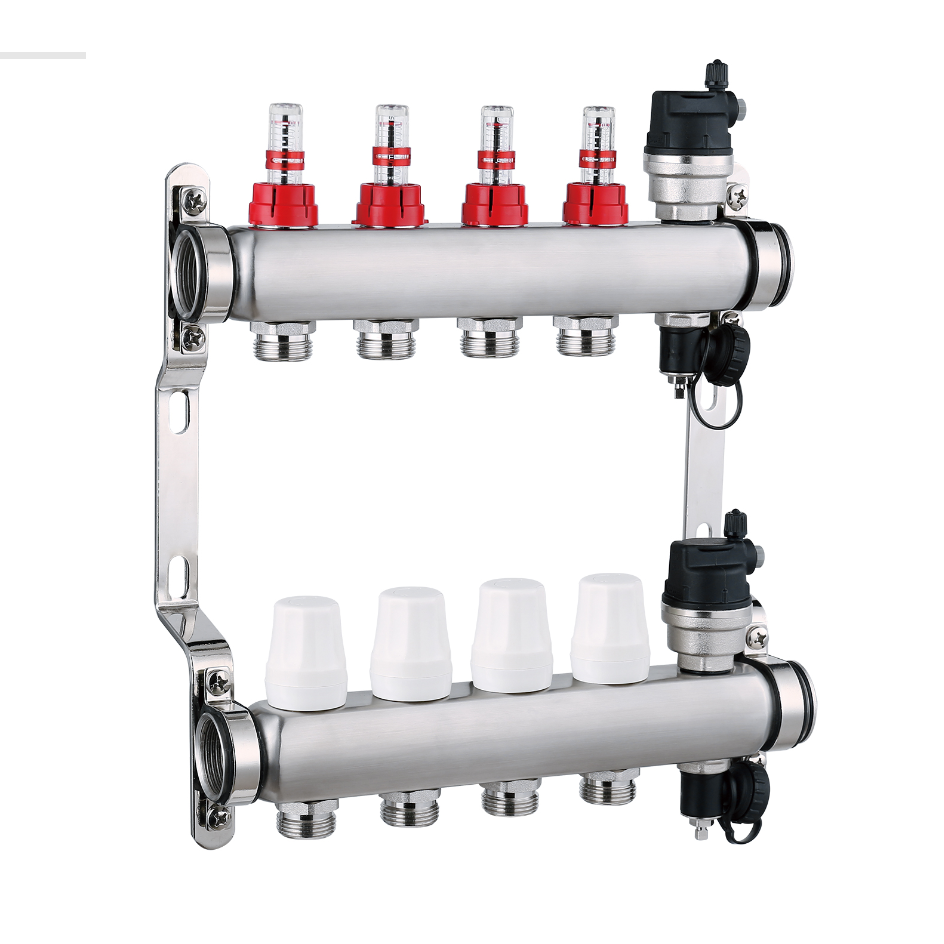

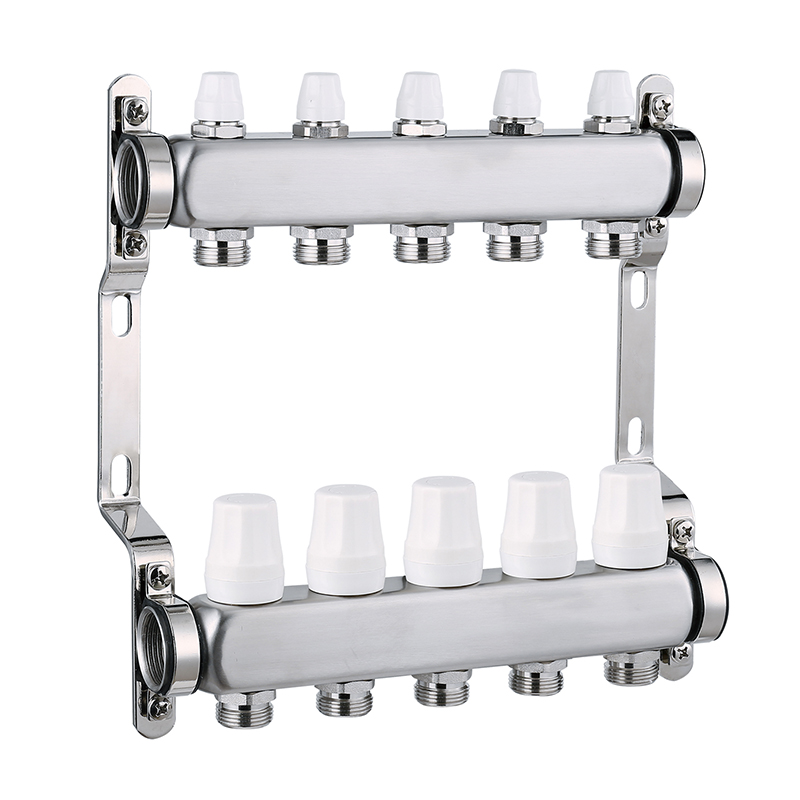

304 Stainless Steel Manifold - Leading Manufacturer in China

When it comes to high-quality manifolds, our 304 stainless steel manifold stands out in the market. Sourced from trusted manufacturers in China, this product not only offers exceptional durability but also great resistance to corrosion, making it ideal for various applications. I’ve seen firsthand how its robust design can enhance performance and longevity in systems requiring efficient fluid distribution. Choosing a 304 stainless steel manifold means investing in reliability. My experiences working with different suppliers have shown that the craftsmanship in China often exceeds expectations. With our manifold, you’ll enjoy superior functionality and peace of mind knowing you have a product that meets rigorous industry standards. Let’s face it, in the fast-paced world of business, you need a solution that works. Our manifold does just that, ensuring optimal flow and seamless integration. If you’re seeking dependable components for your projects, this is the stainless steel manifold you won’t want to miss.

304 Stainless Steel Manifold Application Industry Giant

In today's competitive industrial landscape, the significance of reliable and efficient components cannot be overstated. Among these, 304 stainless steel manifolds have emerged as a vital element across various sectors due to their exceptional corrosion resistance, durability, and versatility. These manifolds play a critical role in fluid distribution systems, ensuring optimal performance and efficiency in heating, ventilation, and air conditioning (HVAC) applications, particularly in commercial and industrial settings. The demand for 304 stainless steel manifolds is driven by their adaptability in diverse industries – from petrochemical and pharmaceutical processing to food and beverage manufacturing. Their inherent resistance to rust and oxidation makes them particularly suitable for environments prone to moisture and corrosive substances, effectively prolonging service life and reducing maintenance costs. Furthermore, as industries move towards more sustainable practices, the recyclable nature of stainless steel is increasingly becoming a deciding factor for global procurement strategies. With a growing emphasis on energy efficiency and innovative solutions, businesses worldwide are seeking trusted partners who understand the intricacies of their operational needs. Investing in quality stainless steel manifolds can significantly enhance system efficiency and reliability. As industries continue to evolve, staying ahead of these trends and embracing high-quality components is essential for procurement specialists looking to foster robust supply chains and achieve long-term success.

304 Stainless Steel Manifold Application Industry Giant

| Application Industry | Material Type | Temperature Resistance (°C) | Pressure Rating (bar) | Corrosion Resistance |

|---|---|---|---|---|

| Chemical Processing | 304 Stainless Steel | 800 | 20 | Good |

| Oil and Gas | 304 Stainless Steel | 650 | 30 | Moderate |

| Food Processing | 304 Stainless Steel | 500 | 25 | Excellent |

| Pharmaceutical | 304 Stainless Steel | 600 | 18 | Good |

| Marine Engineering | 304 Stainless Steel | 580 | 15 | Fair |

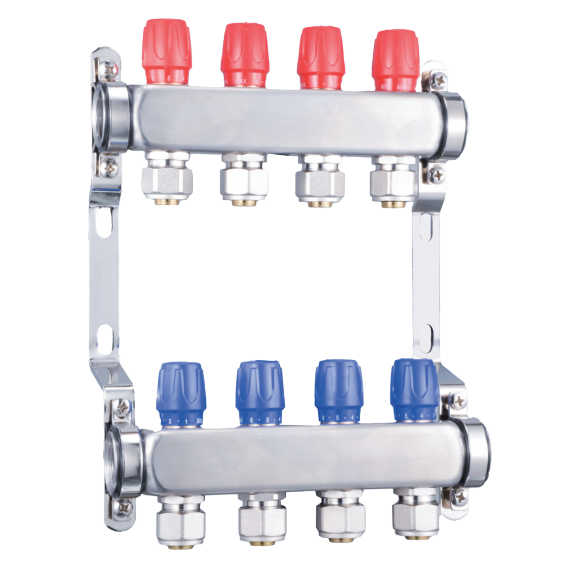

Related Products