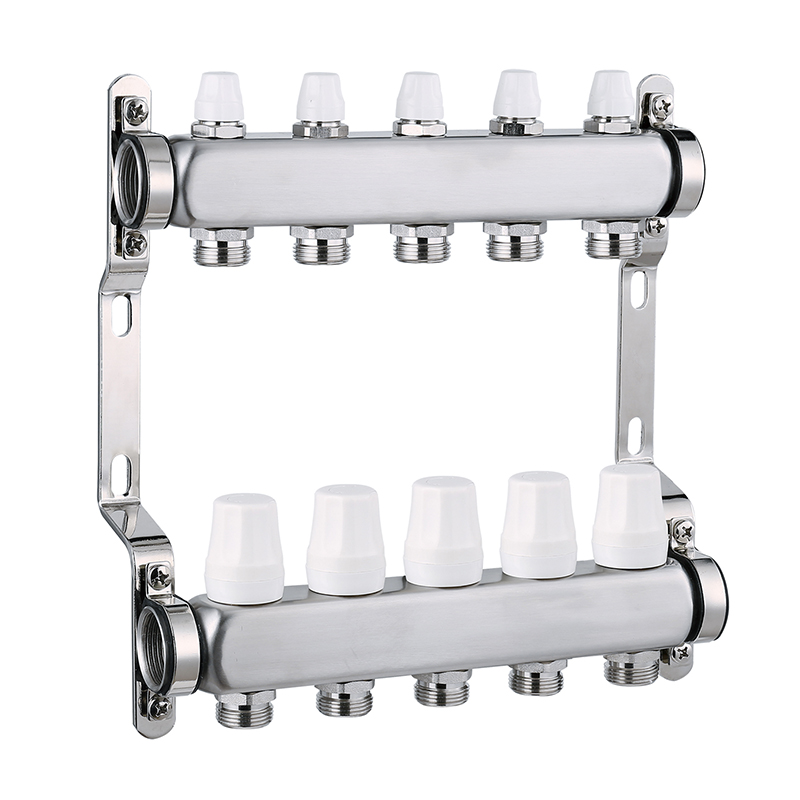

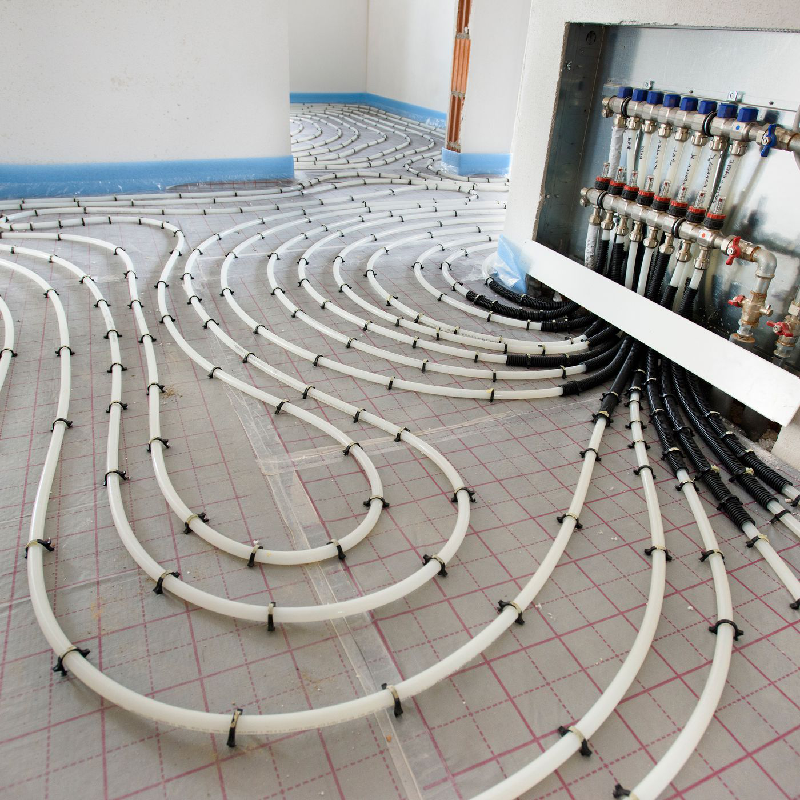

Stainless steel Manifold with flow meter ball valve and drain valve

| Warranty:2 Years | Post-sales Service: Online technical support |

| Brass Project Solution Capability: | graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation |

| Application: Apartment | Design Style: Modern |

| Place of Origin:Zhejiang, China | Brand Name: SUNFLY |

| Model Number: XF26017C |

Type:Floor Heating Systems |

|

Keywords: Stainless steel Manifold |

Color:Raw surface |

|

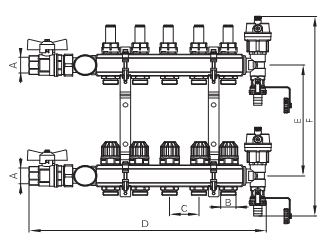

Size:1,1-1/4”,2-12WAYS |

MOQ:1 set |

| Product name: Stainless steel Manifold with flow mater ball valve and drain valve | |

Product material

Stainless Steel

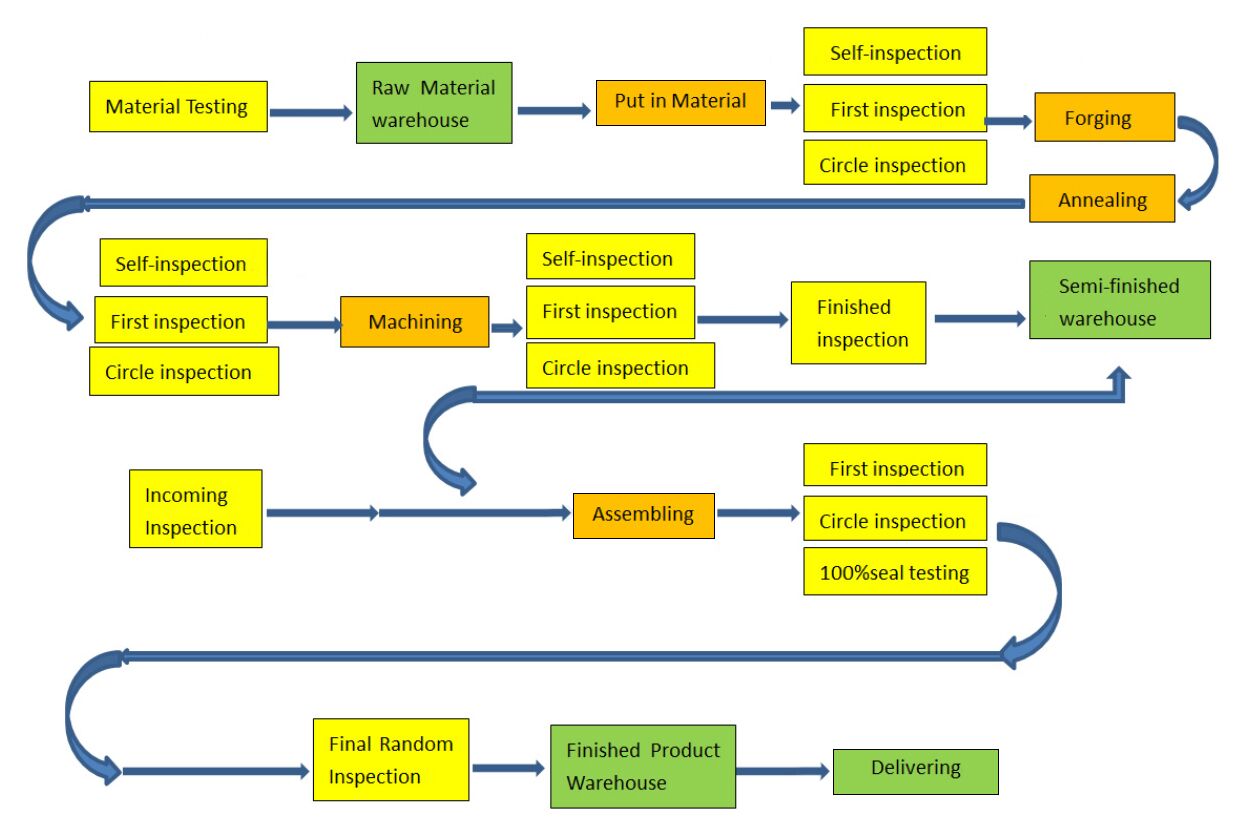

Processing Steps

Applications

Hot or cold water, manifold for floor heating, heating system, mix water system, construction materials etc.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

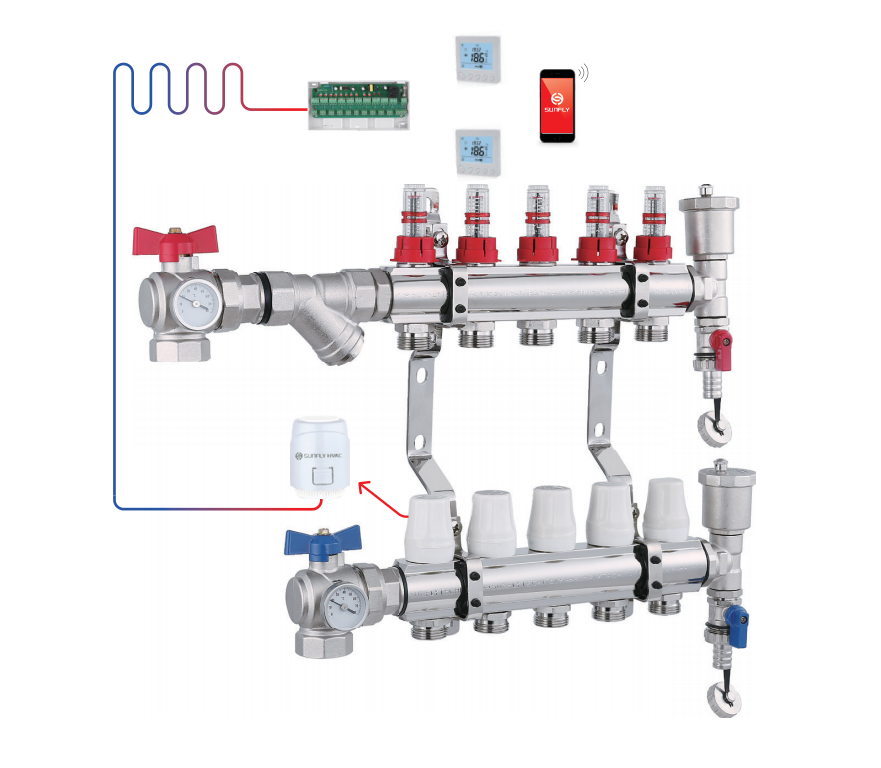

The water mixing center is a water temperature and flow control system composed of a circulating water pump, an electric regulating valve, a ball valve with a thermometer, a controller, a temperature sensor, a filter valve, and a sub-catchment device.

The role of mixing center

The water mixing center adjusts the temperature of the high-temperature water provided by the wall-hung boiler through a thermostat and a regulating valve, and converts it into low-temperature water required for floor heating.

While adjusting the water temperature, the circulation pump can also be used to adjust the flow rate to improve the overall comfort of the floor heating.

In addition to these two main functions, the water mixing center also has functions such as reducing the temperature fluctuation of the outlet water of the wall-hung boiler.

Considering the safety and comfort of floor heating, the floor heating water temperature required by the national standard is not more than 60℃, and the suitable temperature is 35℃~45℃.

If the water outlet temperature of the wall-hung boiler is set at 45°C, it will be in a low-load operation state, and the thermal efficiency will often be lower than the optimal value, which also brings two problems:

1. The low temperature operation of the wall-hung boiler is likely to cause frequent start and stop of the equipment, which will increase the energy consumption and affect the service life of the wall-hung boiler.

2. Insufficient combustion of gas aggravates the carbon deposit of wall-hung boilers, which affects the normal use of wall-hung boilers for a long time.

PS: If it is a condensing furnace suitable for low-temperature operation, the above problems will not occur.

The installation of the water mixing center allows the wall-hung boiler heat source and the floor heating terminal to work in their respective suitable working conditions at the same time, which improves the efficiency of the system and reduces the frequent start and stop of the wall-hung boiler to a certain extent.

Secondly, the water mixing center will provide accurate water temperature and flow according to the needs of the room. While improving comfort, it also reduces energy consumption to a certain extent.