Brass manifold

| Warranty: | 2 Years | Model Number: | XF20162B |

| After-sale Service: | Online technical support | Type: | Floor Heating Systems |

| Product name: | Brass Manifold | Keywords: | Heating manifold |

| Brand Name: | SUNFLY | Color: | Nickel plated |

| Application: | Apartment | Size: | 1,1-1/4”,2-12WAYS |

| Design Style: | Modern | MOQ: | 1 sets brass manifold |

| Place of Origin: | Zhejiang, China | ||

| Brass Project Solution Capability: | Graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

Product material

Brass Hpb57-3(Accepting other copper materials with customer-specified, such as Hpb58-2,Hpb59-1,CW617N,CW603N and so on)

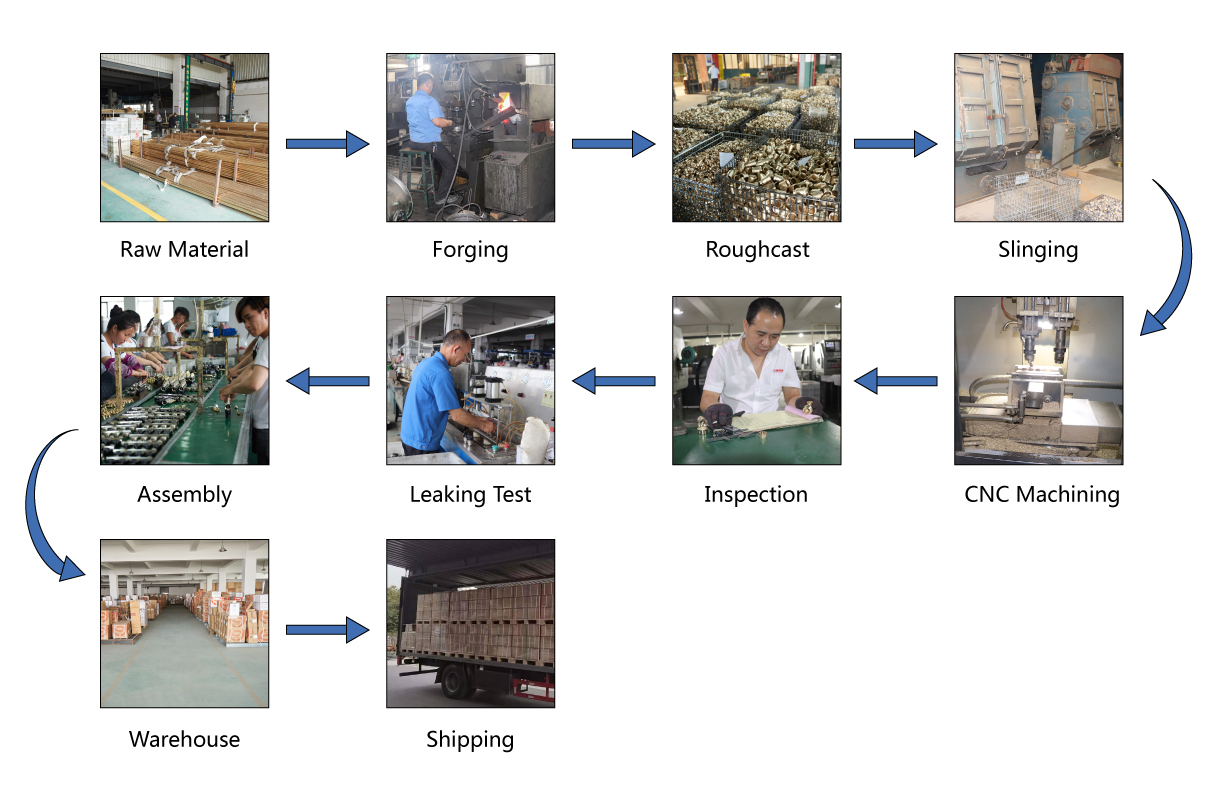

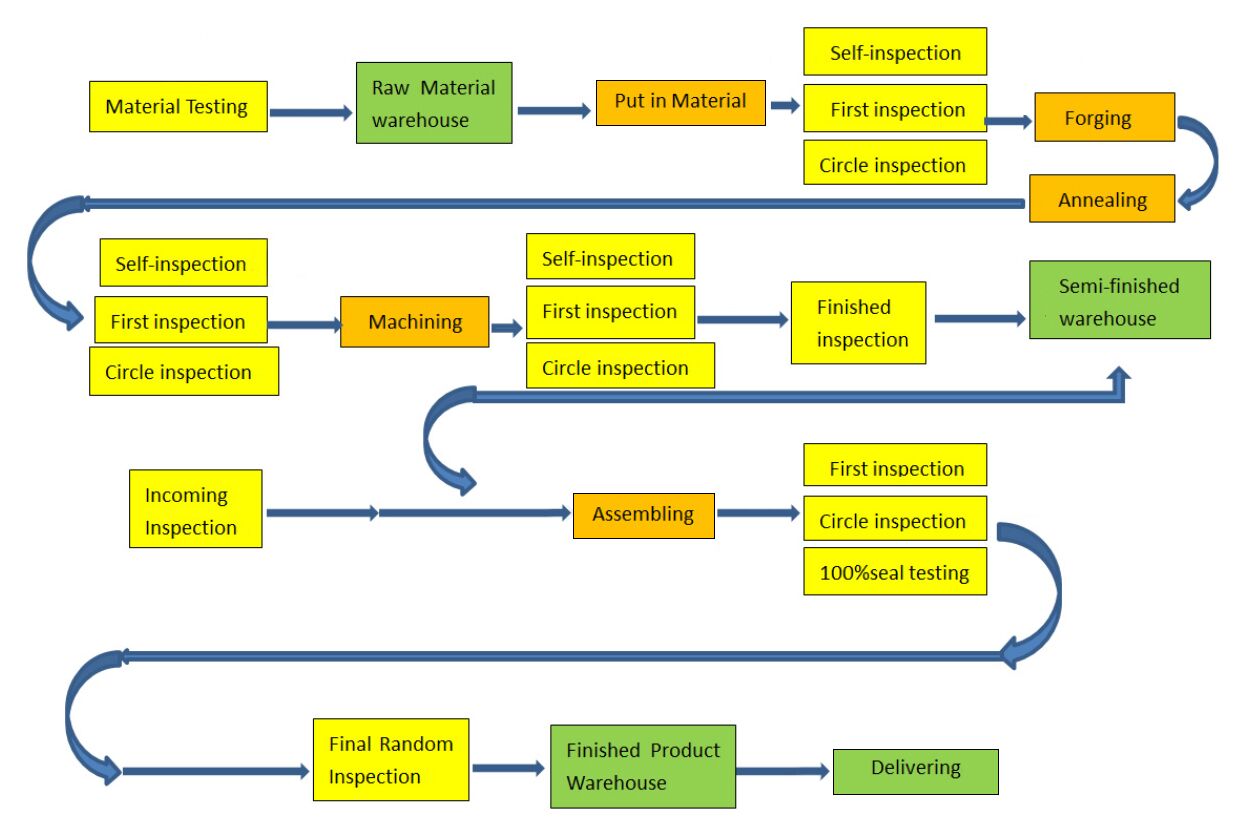

Processing Steps

Raw Material, Forging,Roughcast, Slinging, CNC Machining, Inspection, Leaking Test, Assembly, Warehouse, Shipping

Material Testing, Raw Material Warehouse, Put In Material, Self-Inspection, First Inspection, Circle Inspection, Forging, Annealing, Self-Inspection, First Inspection, Circle Inspection, Machining, Self-Inspection, First Inspection, Circle Inspection, Finished Inspection, Semi-Finished Warehouse, Assembling, First Inspection, Circle Inspection, 100% Seal Testing, Final Random Inspection, Finished Product Warehouse, Delivering

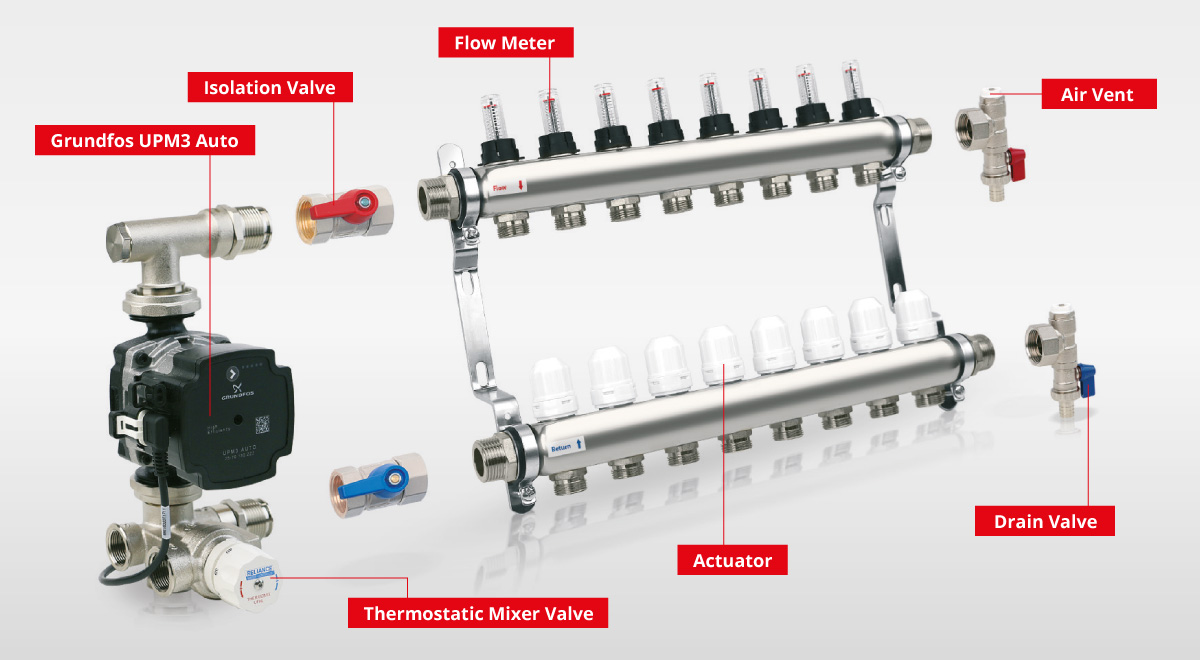

Applications

Hot or cold water, heating system, mix water system, Construction materials etc.

Main Export Markets

Europe, East-Europe, Russia, Middle-Asia, North America, South America and so on.

Product description

How to choose a good manifold?

1. Check whether it meets the heating demand.

Commonly used water separator materials on the market include copper, stainless steel, and other synthetic materials. Different materials have different prices and heating performance. Therefore, when choosing a water separator, you must choose the appropriate material for the water separator according to your own heating needs to avoid any impact on future use.

2. Understand whether the product structure could installed easily.

The installation of floor heating water separators requires certain skills, so before buying, it is necessary to understand which type of water separator is better to install and more suitable for your own home use. The common installation methods of the water separator are: welding and assembling. It is necessary to choose the appropriate installation method. This is a great skill when purchasing the water separator.

3. The material quality must be excellent.

In order to reduce the replacement cost of the water separator when purchasing products, you should consider whether the material is durable. For example, the oxidation resistance and corrosion resistance of the material, and whether the heating operation will produce a lot of scale.

4. The processing technology should be precise.

When purchasing a water separator, it is important to look carefully at the degree of precision of material processing. If the quality of the water separator is rough and the quality of the product is poor, it will affect the normal operation of the floor heating, and in severe cases, it will cause safety hazards due to parts falling off.