Factory directly Mixing Underfloor Heating System - Hydraulic Separator Tank For Radiant Heating – Xinfan

Factory directly Mixing Underfloor Heating System - Hydraulic Separator Tank For Radiant Heating – Xinfan Detail:

Product Details

| Warranty: | 2 Years | Number: | XF15005C |

| After-sale Service: | Online technical support | Type: | Floor Heating Systems |

| Style: | Modern | Keywords: | Hydraulic Separator Tank For Radiant Heating |

| Brand Name: | SUNFLY | Color: | Nickel plated |

| Application: | Apartment | Size: | 3/4” ,1”,1 1/2”,1 1/4” |

| Name: | Hydraulic Separator Tank | MOQ: | 20 sets |

| Place of Origin: | Zhejiang, China | ||

| Brass Project Solution Capability: | Graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

Product parameters

|

Specifications SIZE: 3/4” ,1”,1 1/2”,1 1/4”, |

Product material

Hpb57-3,Hpb58-2,Hpb59-1,CW617N,CW603N,or Customer designated other copper materials,SS304.

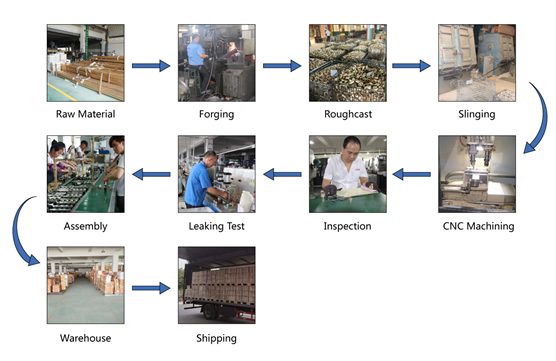

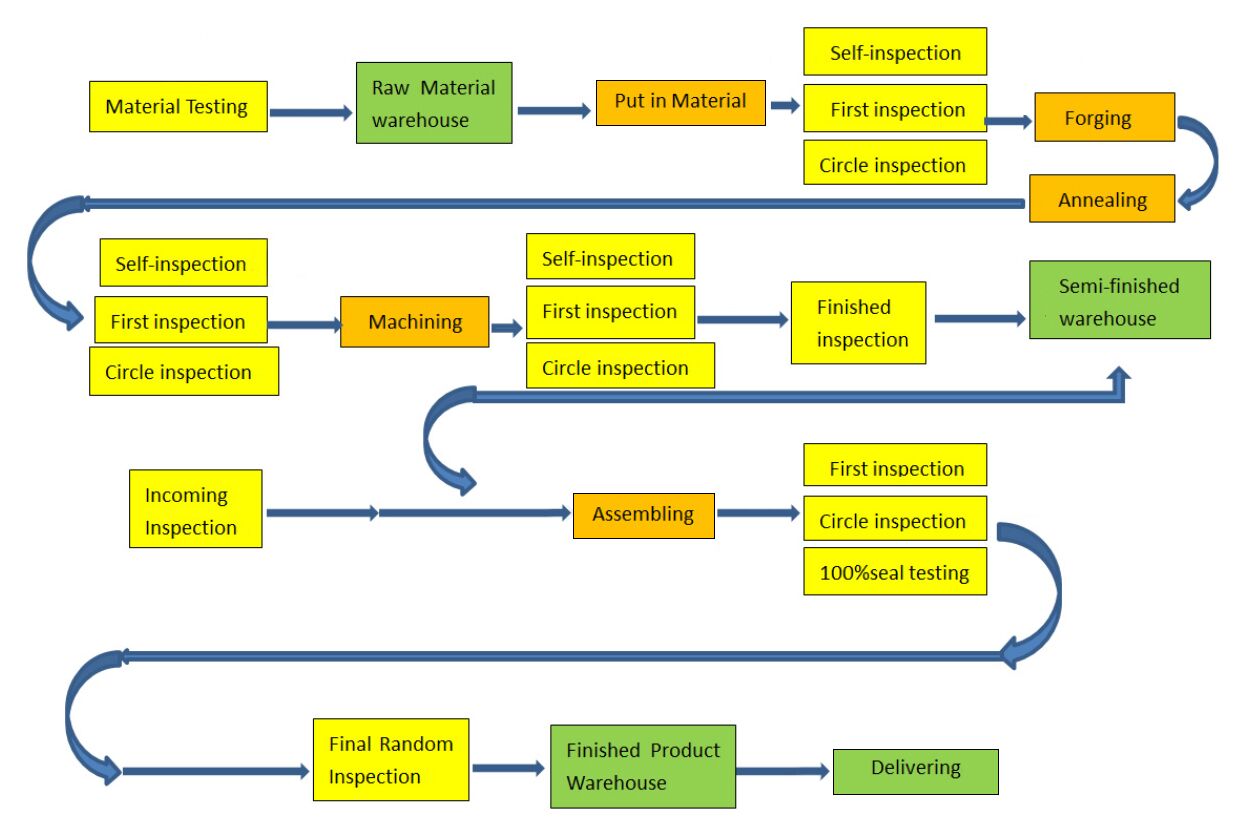

Processing Steps

Raw Material, Forging,Roughcast,Slinging, CNC Machining,Inspection,Leaking Test, Assembly,Warehouse,Shipping

Material Testing, Raw Material Warehouse, Put In Material, Self-Inspection, First Inspection, Circle Inspection, Forging, Annealing, Self-Inspection, First Inspection, Circle Inspection, Machining, Self-Inspection, First Inspection, Circle Inspection, Finished Inspection, Semi-Finished Warehouse, Assembling, First Inspection, Circle Inspection, 100% Seal Testing, Final Random Inspection, Finished Product Warehouse, Delivering

Applications

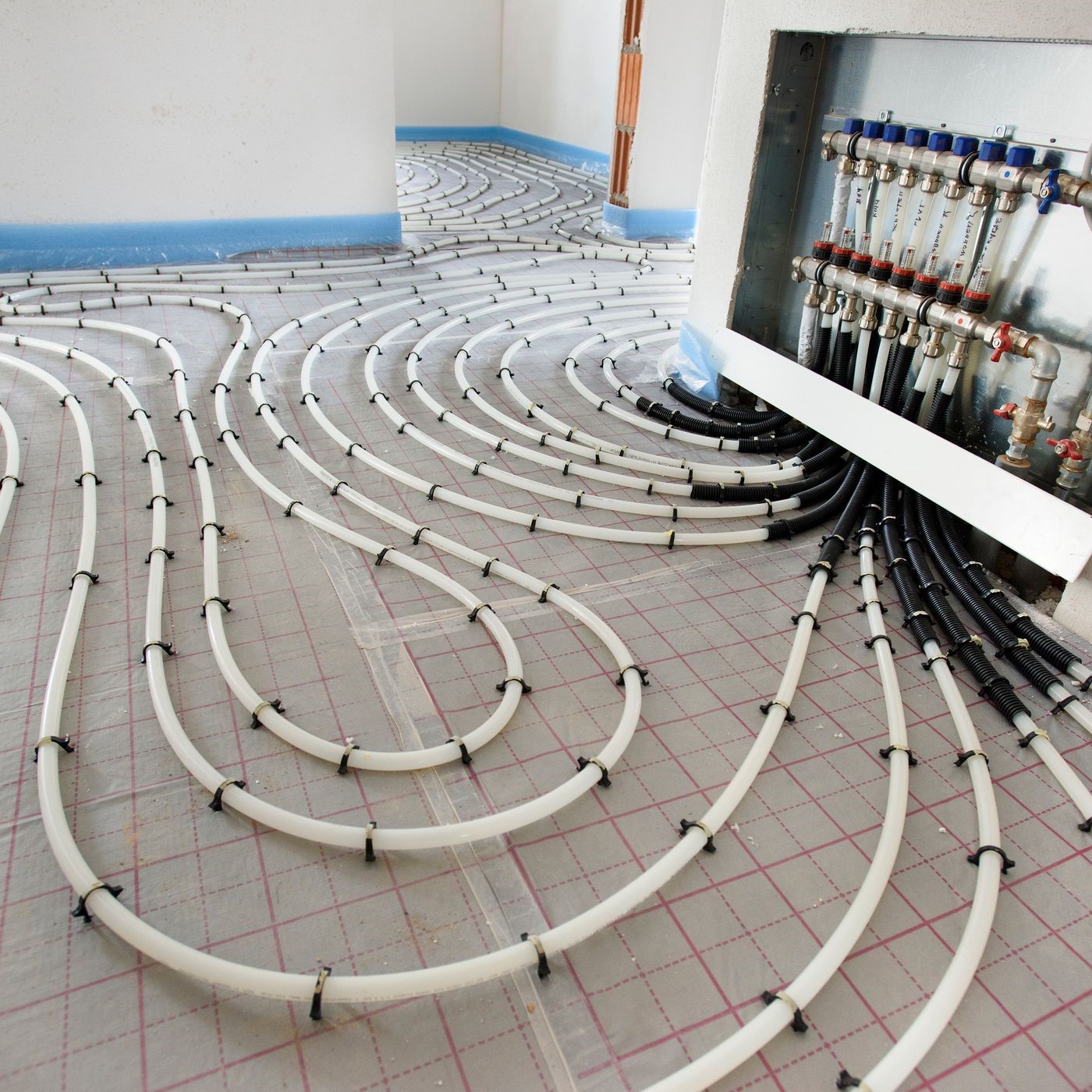

Hot or cold water,heating system,mix water system,Construction materials etc.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

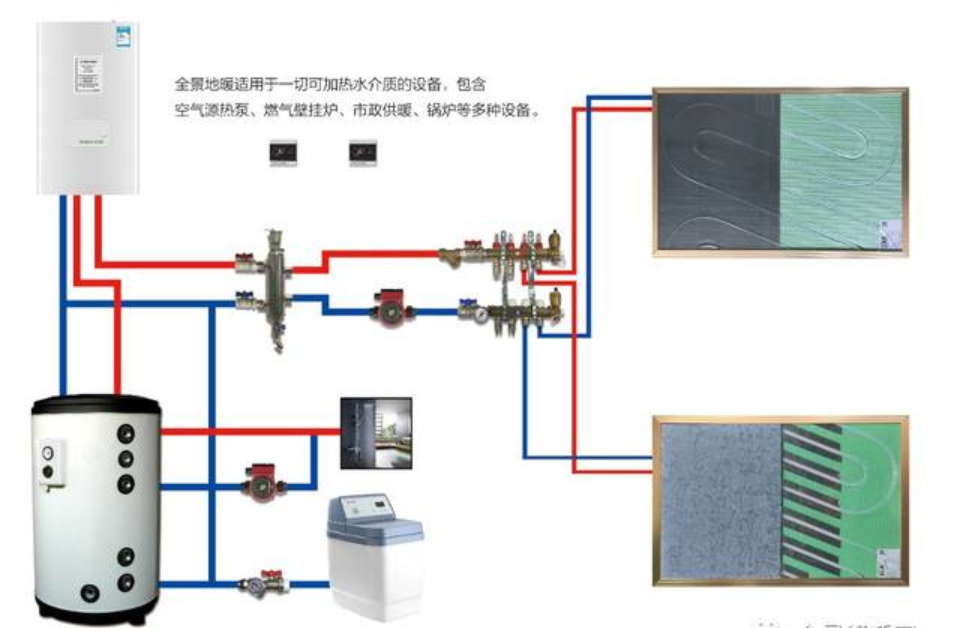

【Main function of coupling tank】

1. In a traditional heating system, all circulating pipes are connected to a common collector. In this system, the function of the water pump will be affected by the water pumps in other systems. The purpose of the coupling tank is to separate the different circulation pipelines in the heating system so that they are not affected by each other.

2. In the wall-hung boiler system, the user will adjust the operating temperature of each room by using an electric temperature control valve or manually adjusting the temperature control valve, which will lead to changes in the flow and pressure in the heating system. The main function of the coupling tank is to balance the pressure in the wall-hung boiler system and the heating system, without any influence on the flow rate of the wall-hung boiler system.

3. On the other hand, for the closed small boiler heating system, the application of the coupling tank can avoid the waste of energy caused by frequent start-up of the boiler, and at the same time play a role in protecting the boiler.

4. Installing a coupling tank in the floor heating system can realize the technical advantages of the floor heating system with large flow and small temperature difference. In the wall-hung boiler operating system, the coupling tank divides the system into a primary system and a secondary system. The function of the coupling tank is to isolate the hydraulic coupling between the primary side and the secondary side so that the hydraulic conditions do not affect each other.

5. During the operation of the system, bubbles will be generated and impurities will accumulate. Therefore, the upper part of the coupling tank will be equipped with an automatic exhaust valve, and the lower part of the coupling tank will be equipped with a sewage valve. After the application of the coupling tank, the original “big cycle” or boiler plus user consisting of a water pump has been changed to an independent cycle for each circuit, which is convenient for management and adjustment, and can also improve operating efficiency and save energy consumption.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won a good popularity amid consumers everywhere in the environment for Factory directly Mixing Underfloor Heating System - Hydraulic Separator Tank For Radiant Heating – Xinfan , The product will supply to all over the world, such as: Angola, Pakistan, Swiss, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!