Brass manifolds are a highly effective solution for a range of fluid control applications, from heating and cooling systems to industrial process control. The unique properties of brass make it a highly suitable material for manifold manufacturing, setting it apart from other materials used in this context. In this article, we will explore what makes brass manifolds distinct from those made from other materials.

High Durability and Robustness

Brass is a highly durable and robust material, capable of withstanding the wear and tear associated with continuous use under demanding conditions. Brass manifolds are therefore able to maintain their integrity and functionality over long periods of time, even in high-pressure and corrosive environments. This makes brass manifolds an excellent choice for applications where reliability and longevity are essential.

Good Thermal Conductivity

Brass has excellent thermal conductivity, making it suitable for use in heating and cooling systems. Brass manifolds are able to distribute heat or coolant efficiently to various points in a system, ensuring uniform temperature control and system efficiency. This characteristic of brass also promotes quick system startups and shutdowns, as well as precise temperature regulation.

Easy to Install and Maintain

Brass manifolds are relatively easy to install and maintain compared to manifolds made from other materials. Brass is a softer material, making it easier to machine and shape during the manufacturing process. This means that brass manifolds can be easily customized to fit specific applications, reducing the need for additional fixtures or fittings during installation. Additionally, brass manifolds are relatively easy to disassemble and clean during maintenance, simplifying the process of inspecting and repairing any issues that may arise.

Resistance to Corrosion

Brass is highly resistant to corrosion, due to its combination of copper and zinc alloys. This means that brass manifolds are able to withstand a range of acids, alkalis, and other corrosive substances commonly found in industrial processes. They remain functional in these environments, without undergoing significant wear or damage. This extends their lifespan and ensures their long-term efficiency, even in challenging conditions.

Attractive and Cost-Effective

Brass manifolds also offer an attractive appearance, with a unique warm tone that blends well with many industrial settings. This aesthetic appeal can help improve the overall appearance of a facility, while also adding value to the overall design. Additionally, brass is relatively cost-effective compared to some other materials, such as stainless steel or titanium. This makes brass manifolds an economical choice for many applications, without sacrificing performance or durability.

Flexibility in Sizing and Configuration

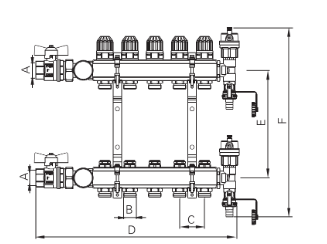

Brass manifolds are available in a range of sizes and configurations, making them easy to adapt to different fluid control systems. Whether you require a small manifold for a domestic heating system or a large one for an industrial process, brass manifolds can typically be tailored to meet your specific needs. This flexibility in design means that brass manifolds can be used across a diverse range of applications, from residential to commercial and industrial settings.

In conclusion, brass manifolds are unique due to their high durability and robustness, good thermal conductivity, ease of installation and maintenance, resistance to corrosion, attractive appearance, cost-effectiveness, and flexibility in sizing and configuration. The combination of these characteristics makes brass a highly suitable material for manifold manufacturing, ensuring longevity and efficiency in a wide range of fluid control applications.

Post time: Sep-29-2023