High-Quality China Manifold Drain Valve from Leading Manufacturers

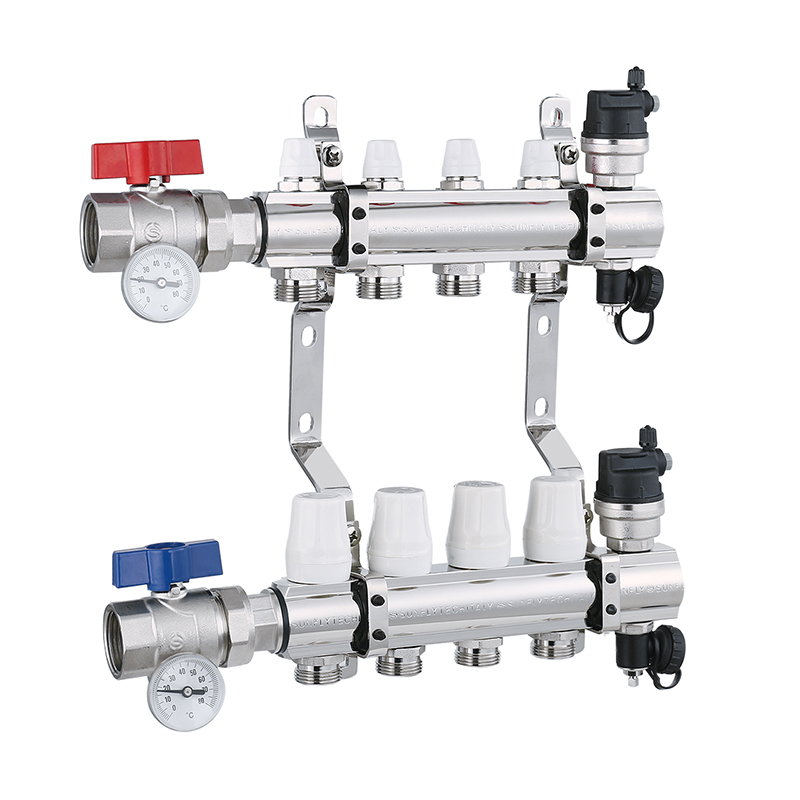

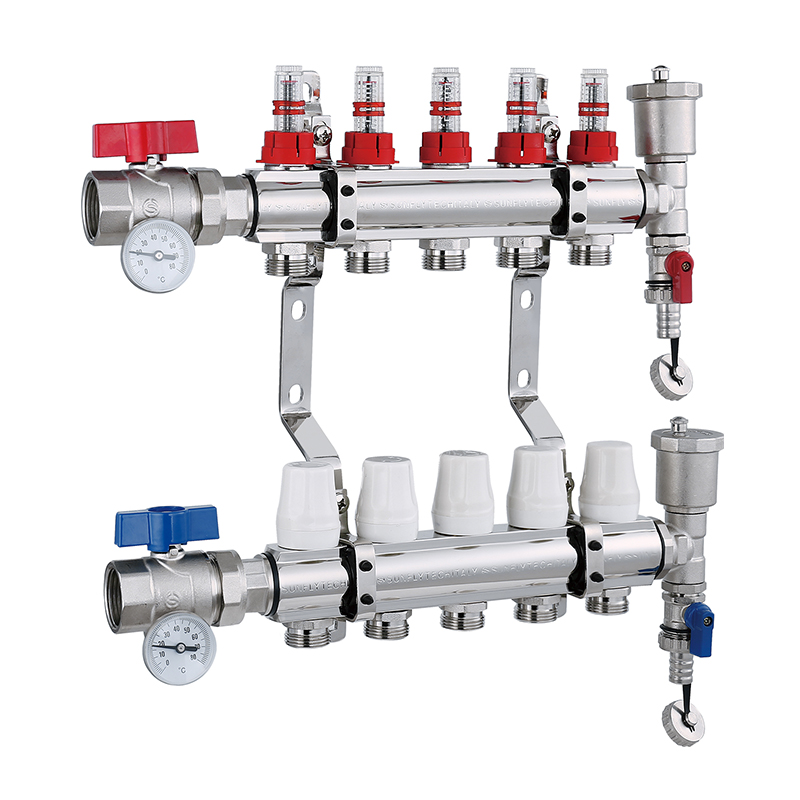

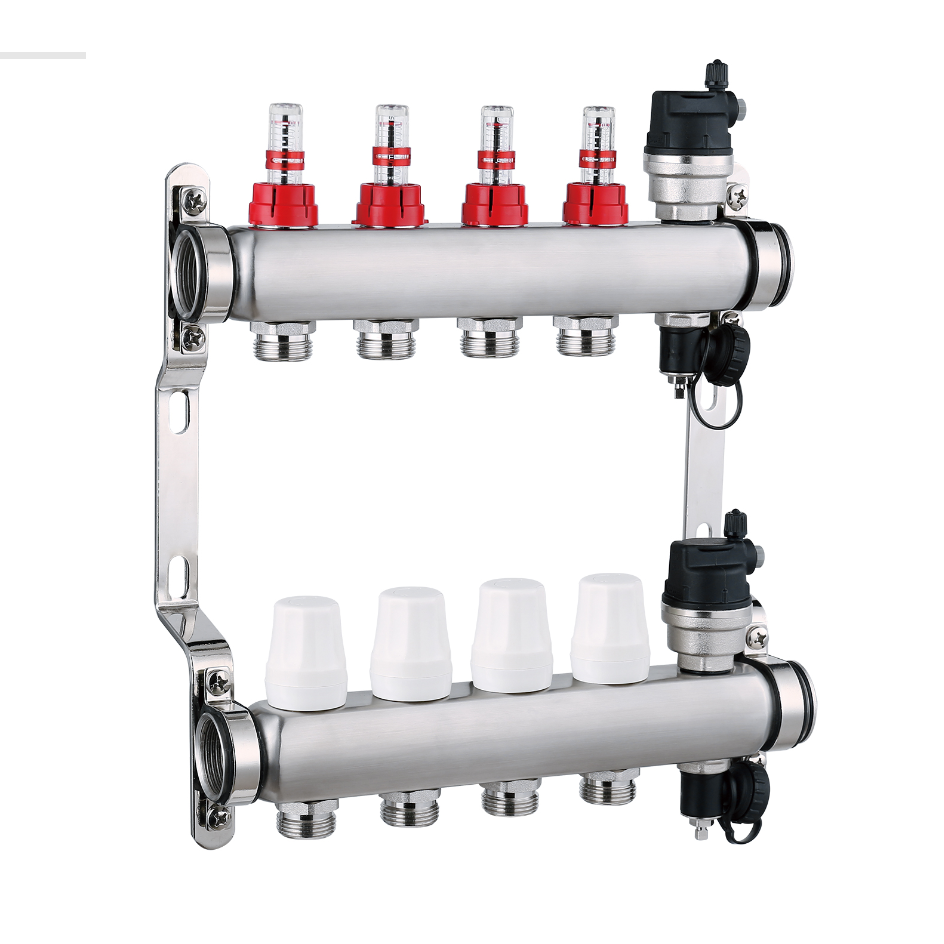

When it comes to sourcing a top-tier China Manifold Drain Valve, I understand the importance of quality. As a B2B purchaser, you want a reliable product that ensures efficient drainage while minimizing leaks. Our high-quality valves are crafted with precision by leading manufacturers in the industry, guaranteeing durability and performance. With a design that prioritizes functionality, these valves are ideal for various applications, from industrial systems to commercial uses. I know that finding the right fit is crucial, and we offer a range of options to meet your specific needs. Choosing our China Manifold Drain Valve is not just about the product; it’s about partnering with trusted experts who prioritize excellence. By focusing on quality and consistent supply, you can enhance your operations, reduce downtime, and ultimately increase your bottom line. Let’s work together to elevate your workflow with the best valves available in the market!

China Manifold Drain Valve Ahead of the Curve Winning in 2025

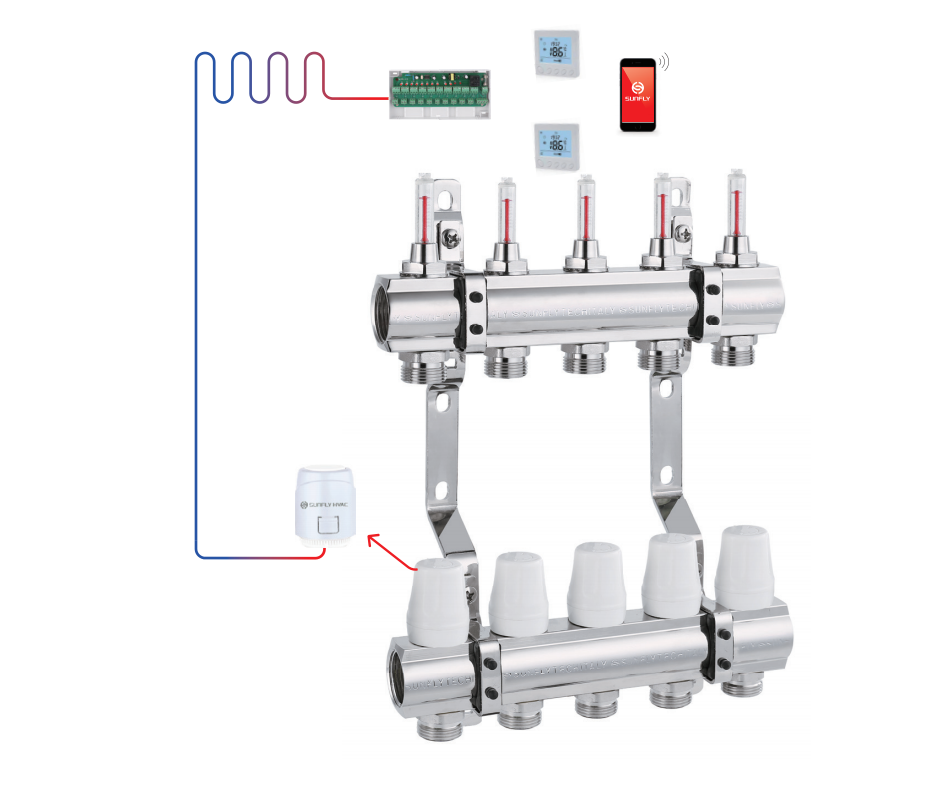

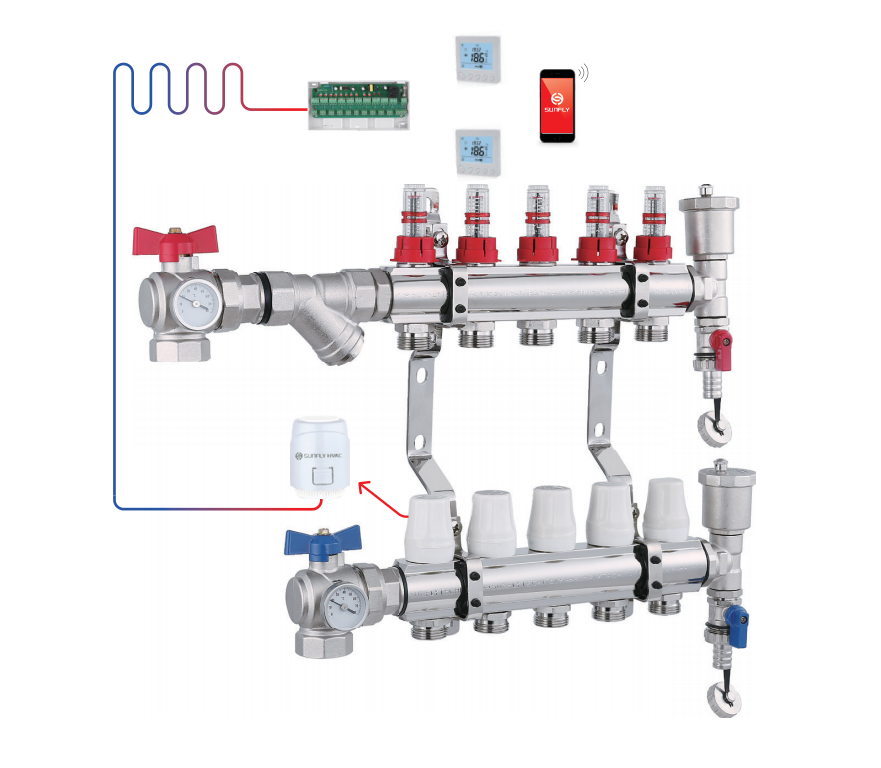

As the global demand for efficient and reliable HVAC systems continues to rise, the importance of advanced components like manifold drain valves is becoming increasingly evident. With the advent of 2025, manufacturers are stepping up to meet the evolving needs of the market. These innovative drain valves not only enhance the operational efficiency of heating, ventilation, and air conditioning systems but also contribute significantly to energy conservation efforts worldwide. In the competitive landscape of HVAC technology, being ahead of the curve means adapting to trends such as sustainability and smart technology integration. The latest manifold drain valves are designed with cutting-edge features that ensure optimal performance, reliability, and user-friendliness. These valves are engineered to facilitate better drainage, reducing maintenance costs and downtime for HVAC systems, which is critical for global procurement buyers focused on long-term investments and cost efficiencies. Looking ahead, the future of manifold drain valves is characterized by rapid advancements in technology, such as IoT connectivity and smart monitoring systems. Global procurement professionals should pay attention to these developments, as they represent opportunities for improving system performance and decreasing operational expenses. By investing in state-of-the-art technologies, buyers can ensure they are selecting components that not only meet current demands but also prepare them for future challenges in the HVAC sector.

China Manifold Drain Valve Ahead of the Curve Winning in 2025

| Feature | Description | Benefits | Market Trends |

|---|---|---|---|

| Material | High-grade stainless steel | Durability and corrosion resistance | Growing demand for reliable materials |

| Pressure Rating | Up to 100 bar | Handles high-pressure applications | Increase in high-pressure systems |

| Applications | Industrial, agricultural, and municipal | Versatile usage possibilities | Expanding application areas |

| Certifications | ISO 9001, CE | Ensures quality and safety | Increasing regulatory standards |

| Innovation | Smart control integration | Enhanced efficiency and monitoring | Trend towards automation |

Related Products