Nickel plated H valve for heating system

Product Details

Warranty:2 Years After-sale Service: Online technical support

Brass Project Solution Capability: graphic design, 3D model design, total solution for

Projects, Cross Categories Consolidation

Application:House Apartment Design Style:Modern

Place of Origin:Zhejiang, China Brand Name:SUNFLY

Model Number: XF60635B/XF60636B

Type:Floor Heating Systems Keywords: H valve,the connection unit

Color:Nickel plated Size: 1/2” 3/4”

MOQ:1000 Name: Nickel plated H valve for heating system

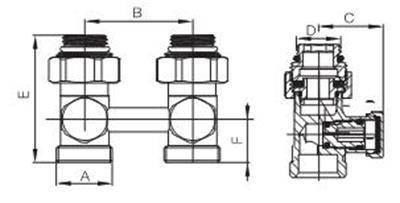

|

1/2” | |

|

3/4” | |

|

A | G3/4” |

| B | 50 | |

| C | 30 | |

| D | G3/4” | |

| E | 62.7 | |

| F | 21 | |

Product material

Brass Hpb57-3(Accepting other copper materials with customer-specified, such as Hpb58-2,Hpb59-1,CW617N,CW603N and so on)

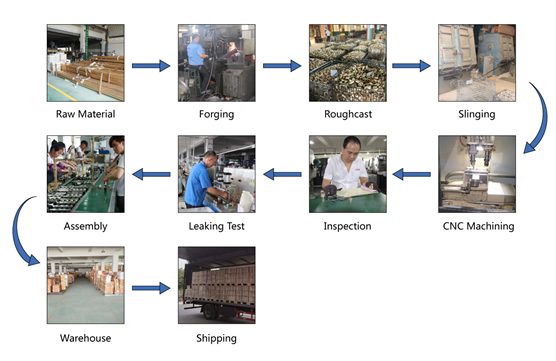

Processing Steps

Raw Material, Forging,Roughcast,Slinging, CNC Machining,Inspection,Leaking Test, Assembly,Warehouse,Shipping

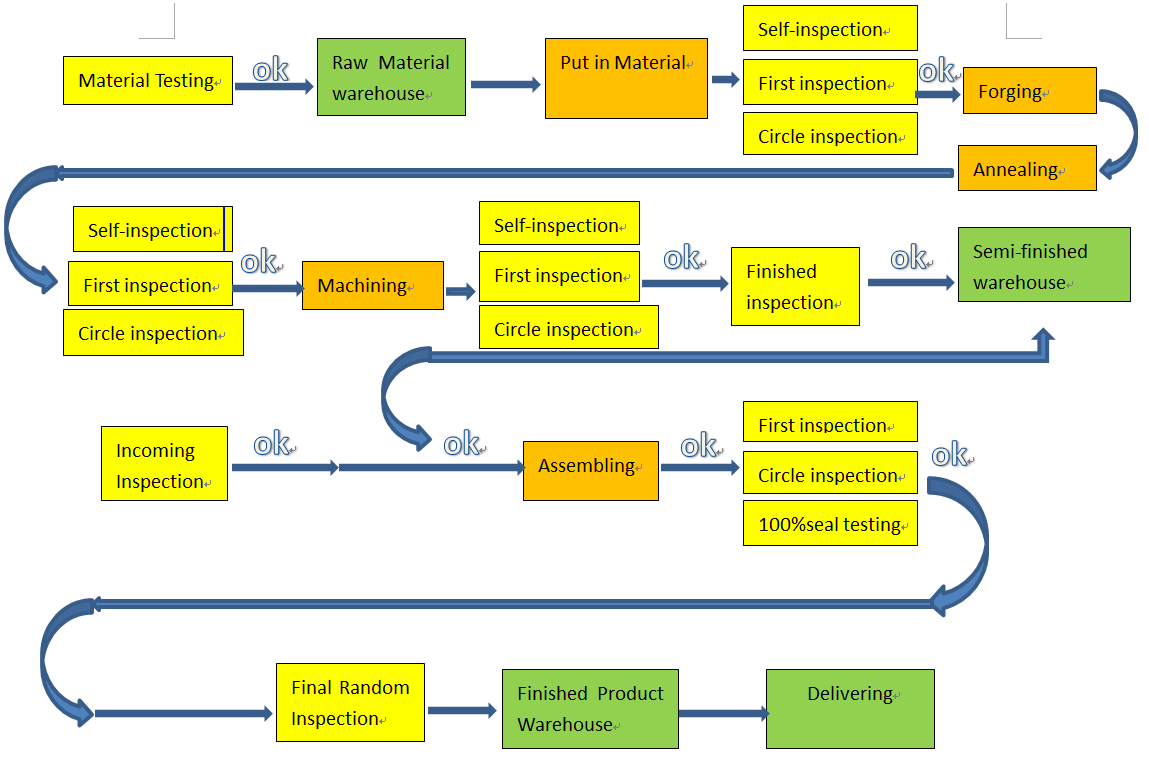

Material Testing,Raw Material Warehouse,Put In Material,Self-Inspection,First Inspection,Circle Inspection,Forging,Annealing,Self-Inspection,First Inspection,Circle Inspection,Machining, Self-Inspection,First Inspection,Circle Inspection,Finished Inspection,Semi-Finished Warehouse, Assembling,First Inspection,Circle Inspection,100% Seal Testing,Final Random Inspection, Finished Product Warehouse,Delivering

Applications

Radiator following,radiator accessories,heating accessories.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product description:

The principle of work:

The radiator connection unit for two-pipe heating systems consists of two valve control valves interconnected,one of which is connected to the supply pipe, the other to the return.

Any flow direction is allowed, as work characteristics are the same in both directions. The flow rate of the coolantthrough the valve is adjusted by rotating the tuning sleeve using a hex wrench.

When the tuning sleeve is rotated clockwise, it lowers down onto the seat, closing the valve. And, conversely,when the sleeve rotates counterclockwise, it rises, opening the valve.

Flow control can be performed during operation. The feed or return radiator pipe can be blocked by turning the adjusting sleeve clockwise until it stops.

Installation instructions:

The radiator connection unit is used in two-pipe heating systems to connect radiators having lower connections with a center distance of 50 mm.

Before installing the unit, the pipeline must be cleaned of rust, dirt, scale, sand and other foreign particles that affect the performance of the product. Heating systems, heat supply at the end of their installation should be washed with water until it comes out without mechanical suspensions .

The direct assembly is used when connecting the radiator to pipes exiting so far, and the corner assembly when connecting to pipes exiting the wall.Connection of the H-shaped assembly to radiators having connecting exits with an external thread is carried out using union nuts (4). If the radiator has connecting outputs with 1/2 “internal thread, then the unit is connected using transitional nipplesYou must firstscrew the adapter nipples into the radiator exits, then attach the assembly and tighten the nuts. The assembly should not experience stress from the pipeline (bending, compression,tension,torsion,distortions,vibration,pipe spacings,non-uniformity of fastening fasteners).If necessary,supports or compensators should be provided to reduce the load on the product from the pipeline.

The weariness of the connected pipelines should not exceed 3 mm with a length of up to 1 m plus 1 mm for each subsequent meter .The assembly should be installed in such a way that free access to the tuning mechanism of shut-off and control valves is provided. Check the installation.

Instructions for use and maintenance:

The radiator connection unit must be operated without exceeding the pressure and temperature given in the table of technical characteristics.

Installation and dismantling of the product,as well as any repair operations should be carried out in the absence of pressure in the system.Allow equipment to cool to ambient temperature.The flow rate adjustment can be carried out during operation. First, completely close the valve.To do this, unscrew the protective cover, and then use the Allen key to rotate the adjustment sleeve clockwise until it stops.

Then you need to configure the required flow rate. To do this, use the same key to turn the tuning sleeve counterclockwise by the required number of revolutions (in accordance with the flow and pressure loss graph).Then screw back the protective cover. The adjustment must only be done either on the supply pipe valve or on the return pipe valve