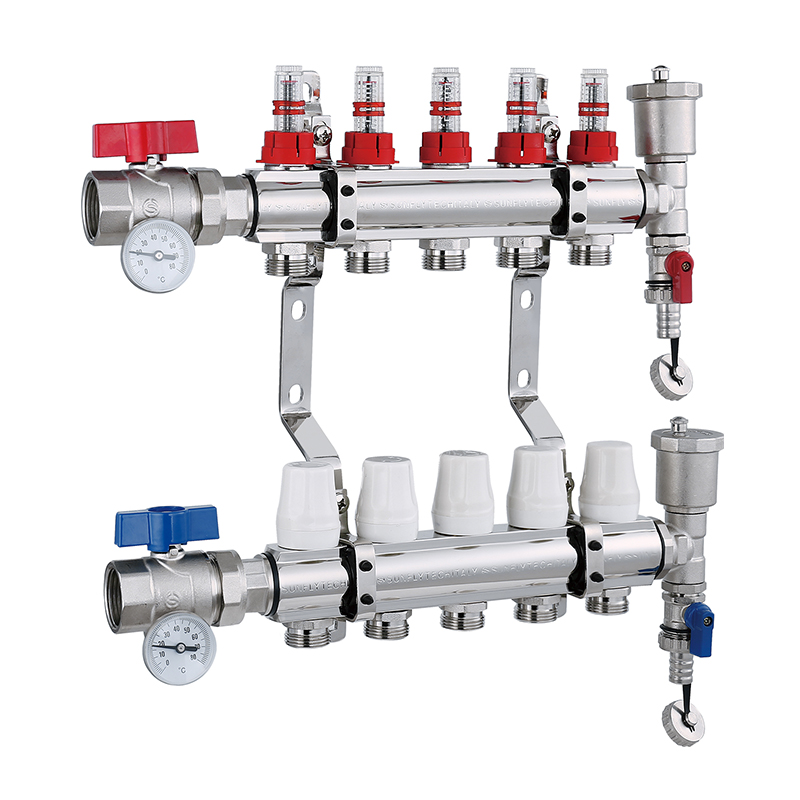

Forged Ball Valve OEM Supplier: Quality Valves for All Applications

When I'm searching for a reliable forged ball valve, I always prioritize quality and performance, especially as an OEM or supplier. Our forged ball valves are crafted from premium materials, ensuring durability and efficiency in demanding applications. They are designed to provide exceptional sealing capabilities and resistance to high pressure and temperature fluctuations, giving you peace of mind during critical operations. I understand that in the B2B world, dependable suppliers are essential for smooth business processes. That's why I strive to maintain high standards and deliver valves that meet stringent industry norms. Our team is always ready to assist you with technical specifications and customization options to fit your unique needs. With competitive pricing and unwavering support, choosing our forged ball valves means you'll have a trusted partner in your supply chain. Let's enhance your operations with our top-notch valve solutions that are built to last!

Forged Ball Valve Leads the Global Market Where Innovation Meets 2025

In a rapidly evolving market, forged ball valves are setting the standard for reliability and innovation, capturing the attention of global buyers. These valves are engineered for optimal performance across various applications, from HVAC systems to industrial processes. The adoption of advanced manufacturing techniques and state-of-the-art materials ensures that these valves not only meet but exceed industry standards for durability and efficiency. As sustainability becomes a priority, the focus on energy-saving features within forged ball valves highlights their role in reducing operational costs while minimizing the environmental impact. As we look towards 2025, the global demand for high-quality forged ball valves is expected to surge. Manufacturers are keenly aware of this shift and are investing in research and development to introduce smart technologies that enhance performance and user experience. This includes integrating automation and remote monitoring capabilities that allow for seamless operation and maintenance, ensuring that industries can adapt to modern challenges. For businesses seeking to optimize their processes, these innovations represent a vital opportunity to improve efficiency and reliability. Moreover, the global marketplace is increasingly competitive, making it essential for buyers to align with manufacturers that prioritize quality and technological advancement. The collaboration between engineering excellence and innovative design will not only lead to superior product offerings but also establish long-term partnerships that drive mutual growth. As the landscape continues to evolve, the emphasis on innovative forged ball valves will undoubtedly pave the way for a more efficient and sustainable future in industrial operations.

Forged Ball Valve Leads the Global Market Where Innovation Meets 2025

| Region | Market Share (%) | Growth Rate (CAGR) | Key Innovations | Sustainability Initiatives |

|---|---|---|---|---|

| North America | 34% | 5.5% | Smart valve technology | Recyclable materials usage |

| Europe | 28% | 4.8% | Leak-proof design | Energy-efficient manufacturing |

| Asia-Pacific | 30% | 6.1% | Advanced sealing technology | Carbon footprint reduction |

| Latin America | 5% | 3.2% | Corrosion-resistant materials | Waste reduction programs |

| Middle East & Africa | 3% | 4.0% | High-temperature resistance | Sustainable sourcing |

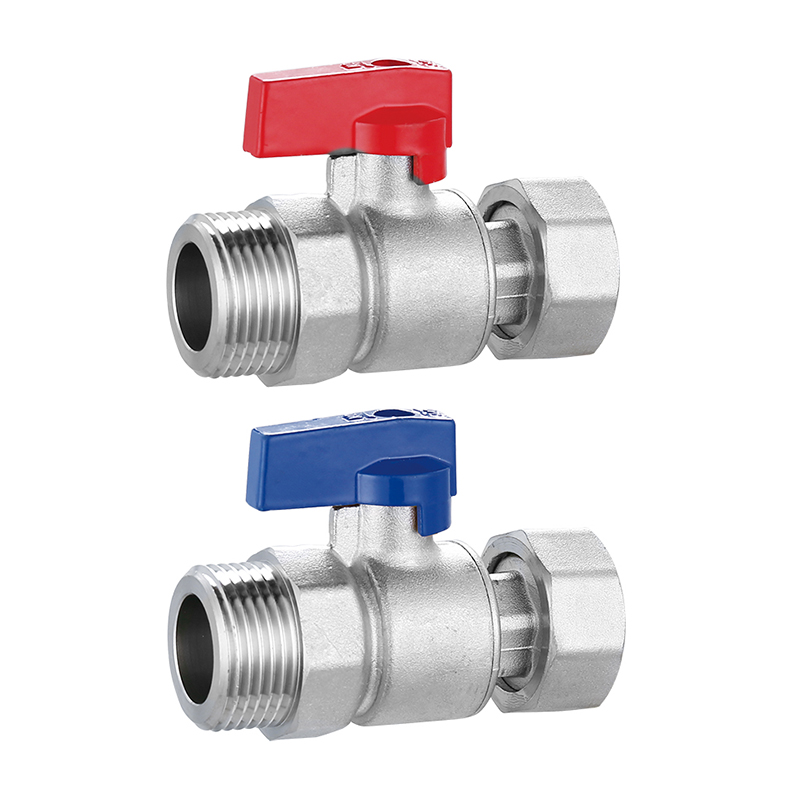

Related Products