High-Quality Brass Ball Valve Manufacturer in China for Your Needs

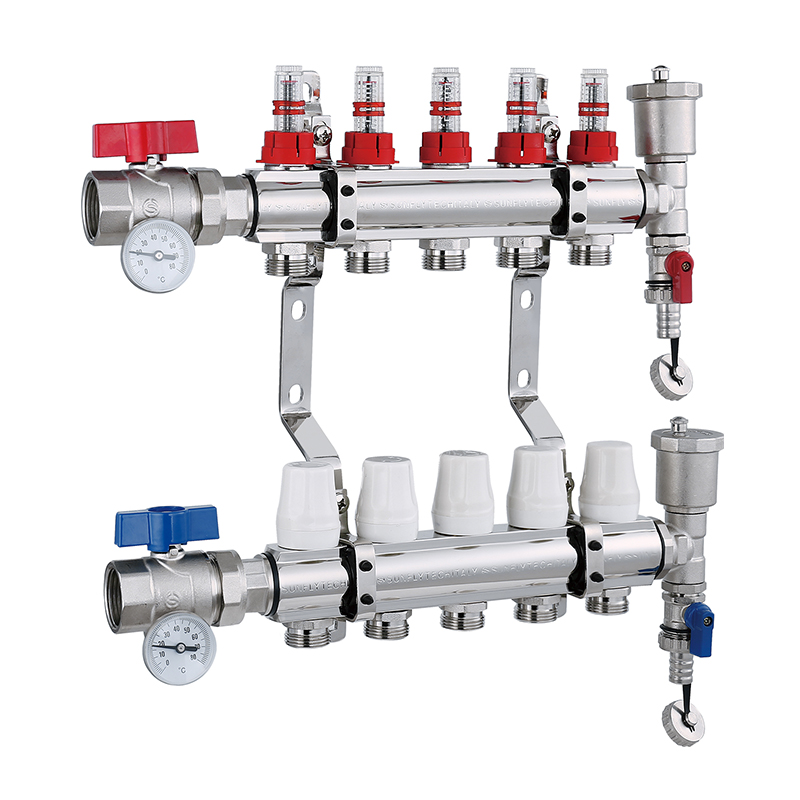

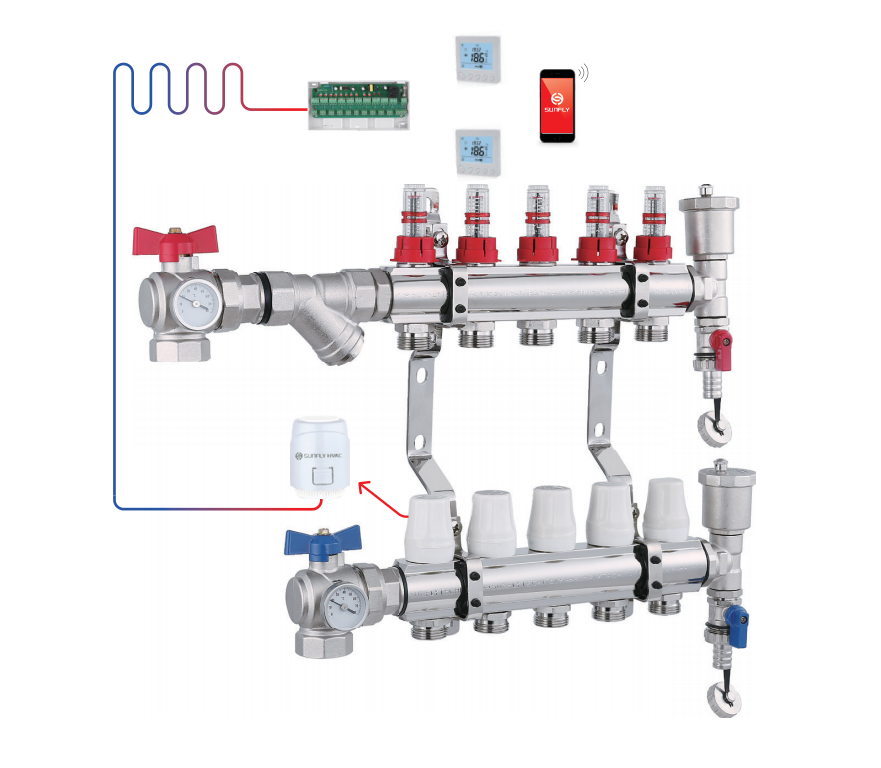

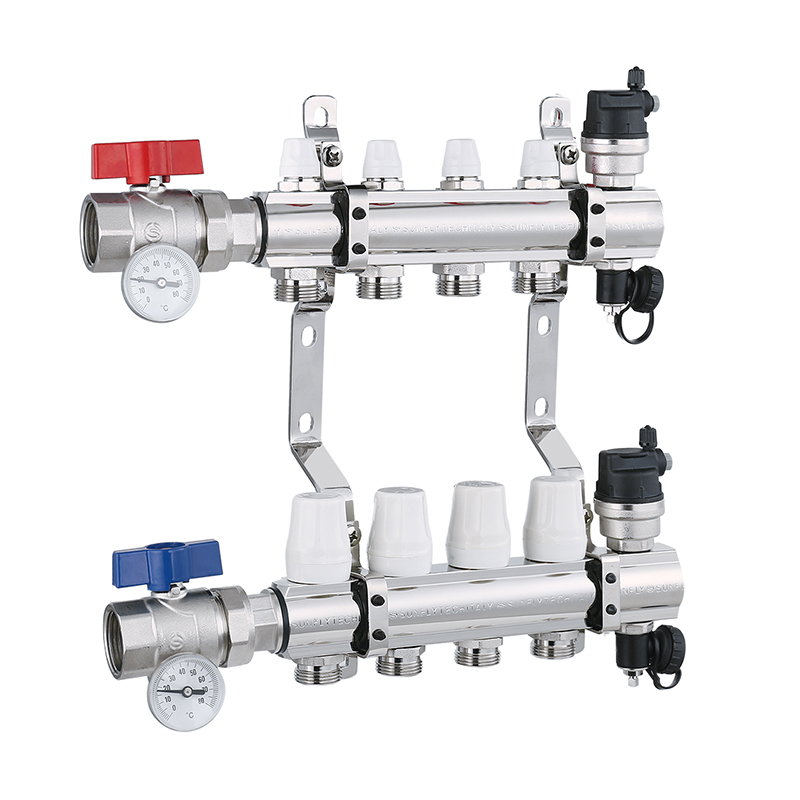

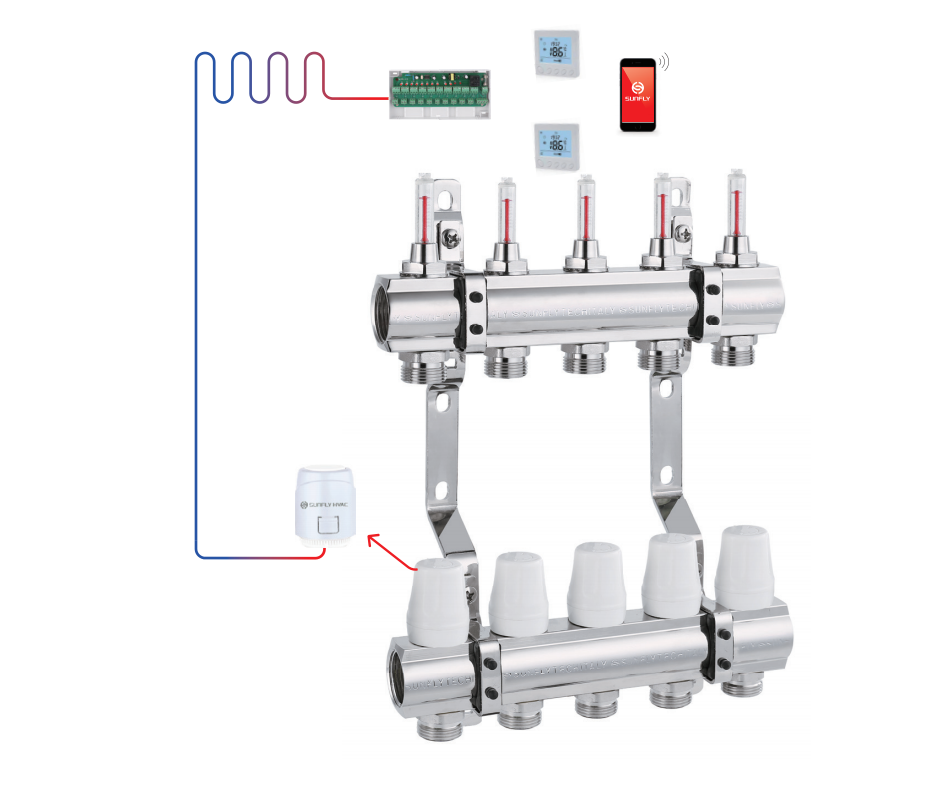

When I think of durable and reliable fittings, the Brass Ball Valve always comes to mind. Sourced directly from China, these valves offer exceptional quality at competitive prices. Whether you are in construction, plumbing, or manufacturing, these valves are designed to withstand high pressures and temperatures, making them ideal for various applications. As a manufacturer, I'm proud to provide a range of sizes and configurations to meet your specific needs, ensuring a perfect fit for any project. The smooth operation and tight sealing of our Brass Ball Valves reduce the risk of leaks, giving you peace of mind. If you're aiming to boost your supply chain with top-notch products, this is definitely something to consider. Let’s connect and explore how our offering can enhance your operations while keeping costs in check!

Brass Ball Valve Factory From Concept to Delivery

In the fast-paced world of HVAC solutions, sourcing quality components is essential for success. A brass ball valve factory that prioritizes every stage of production—from initial concept to final delivery—ensures a product that meets international standards and customer expectations. By integrating advanced manufacturing processes with rigorous quality control, this type of factory offers procurement specialists the reliability and performance necessary for a wide range of applications. The journey begins with a thorough understanding of client requirements, leading to innovative design solutions tailored to specific needs. Advanced materials are carefully selected to guarantee durability and efficiency under various operating conditions. The factory employs state-of-the-art machinery and skilled artisans to fabricate high-quality valves, ensuring precision in every detail. This meticulous attention to quality is matched by efficient logistics, allowing for timely delivery and responsive service for global buyers. Ultimately, partnering with a factory that excels from concept to delivery means gaining access to not only superior products but also reliable support throughout the purchasing process. This comprehensive approach helps businesses stay competitive in a demanding market, making the right choice for procurement essential for sustained growth and customer satisfaction.

Brass Ball Valve Factory From Concept to Delivery

| Stage | Description | Duration | Key Personnel |

|---|---|---|---|

| Concept Development | Initial design brainstorming and requirements gathering. | 2 weeks | Design Team, Product Manager |

| Design & Prototyping | Creating CAD models and building prototypes for testing. | 4 weeks | Engineering Team, Prototyping Specialist |

| Testing & Validation | Conducting performance and safety tests on prototypes. | 3 weeks | Quality Assurance Team, Engineers |

| Manufacturing Preparation | Finalizing production plans and sourcing materials. | 2 weeks | Supply Chain Manager, Production Manager |

| Production | Mass production of brass ball valves according to specifications. | 6 weeks | Production Team, Supervisors |

| Quality Control | Final inspection and quality assurance checks before delivery. | 1 week | Quality Control Team, Inspectors |

| Delivery | Shipping finished products to customers and distribution centers. | 1 week | Logistics Team, Warehouse Staff |

Related Products