Top Famous Suppliers of Pneumatic Safety Valves for Reliable Solutions

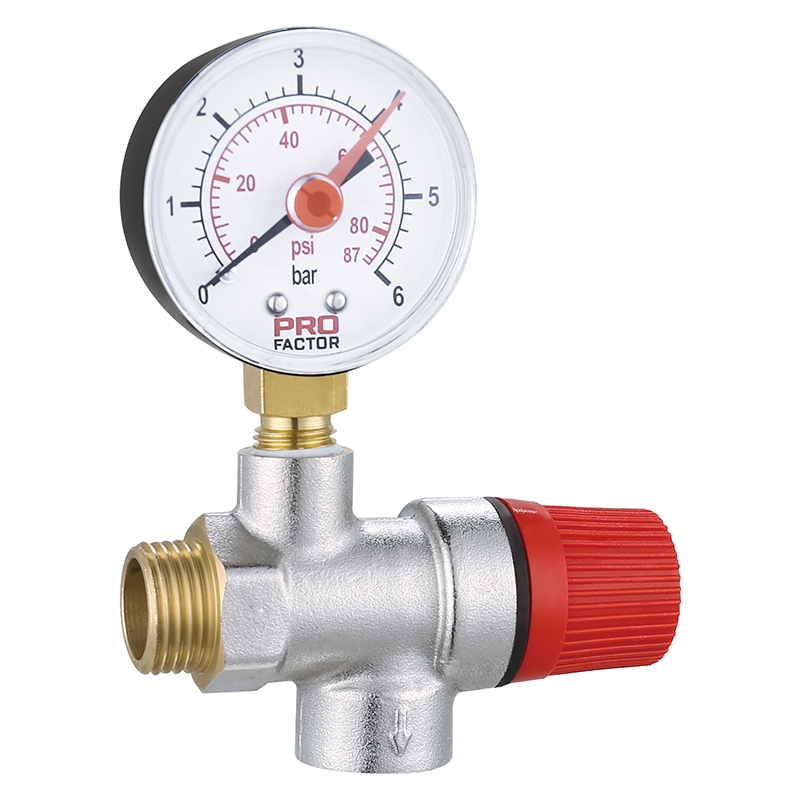

When it comes to ensuring safety in industrial operations, I've found that a Pneumatic Safety Valve is an essential component. These valves are designed to automatically release excess pressure, preventing potential hazards and system failures. I always recommend sourcing from famous suppliers, as they offer the best quality and reliability in their products. In my experience, selecting a Pneumatic Safety Valve from reputable manufacturers not only guarantees superior performance but also contributes to the overall efficiency of operations. Whether you’re in the oil, gas, or manufacturing sector, a trustworthy valve can make a huge difference in safety protocols. When choosing a supplier, I look for those with a solid reputation and proven track records. Make sure to prioritize quality and compliance with industry standards. By investing in a Pneumatic Safety Valve, you're taking a crucial step towards safeguarding your processes and ensuring peace of mind in your operations.

Pneumatic Safety Valve in 2025 Where Innovation Meets 2025

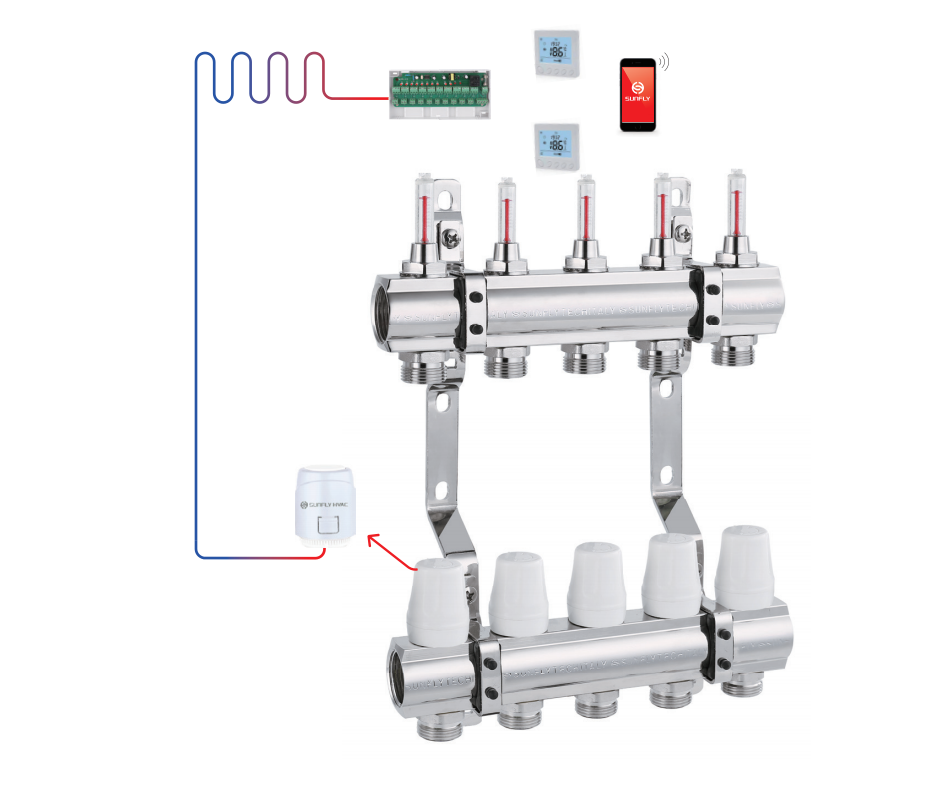

As we approach 2025, the landscape of pneumatic safety valves is evolving, driven by innovation and advancements in technology. These vital components play a crucial role in ensuring safe and efficient operations across various industries, from manufacturing to HVAC systems. The upcoming innovations are set to enhance reliability, increase performance, and reduce maintenance costs, making them indispensable for global procurement departments looking to optimize their supply chains. In the coming years, we can expect pneumatic safety valves to incorporate smart technologies, allowing for real-time monitoring and diagnostics. This will facilitate predictive maintenance, drastically reducing unexpected downtimes and extending the lifecycle of the equipment. Additionally, energy efficiency regulations are driving the development of more sustainable valve solutions that minimize energy consumption while maintaining optimal performance. Global buyers will also find enhanced customization options, enabling them to tailor solutions to specific operational needs. As demand for advanced safety features rises, manufacturers will prioritize safety compliance and implement rigorous testing protocols. Thus, investing in high-quality pneumatic safety valves will not only ensure operational efficiency but will also adhere to increasingly stringent safety standards in diverse applications around the world.

Pneumatic Safety Valve in 2025 Where Innovation Meets 2025

| Feature | Description | Expected Impact | Technological Integration |

|---|---|---|---|

| Smart Monitoring | Real-time monitoring of valve performance using IoT. | Improved reliability and maintenance scheduling. | Integrated with cloud-based platforms for data analysis. |

| Eco-friendly Design | Utilizing recyclable materials to reduce carbon footprint. | Compliance with environmental regulations and sustainability goals. | Supported by green technology initiatives. |

| Enhanced Safety Features | Automatic shut-off and emergency release mechanisms. | Reduction in accidents and enhanced safety in operations. | Synergizes with advanced safety monitoring systems. |

| AI Integration | Predictive analytics for valve performance using AI. | Proactive maintenance and failure prevention. | Incorporated AI algorithms for real-time decision making. |

| Modular Design | Easily replaceable modules for quick repairs or upgrades. | Reduced downtime and maintenance costs. | Compatible with various valve systems and configurations. |

Related Products