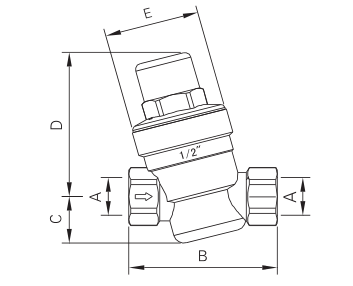

pressure reducing valve

| Warranty: | 2 Years | Number: | XF80832D |

| After-sale Service: | Online technical support | Type: | Floor Heating Systems |

| Style: | Modern | Keywords: | pressure valve |

| Brand Name: | SUNFLY | Color: | Nickel plated |

| Application: | Apartment | Size: | 1/2’’ 3/4’’ |

| Name: | pressure reducing valve | MOQ: | 200 set |

| Place of Origin: | Zhejiang, China | ||

| Brass Project Solution Capability: | Graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

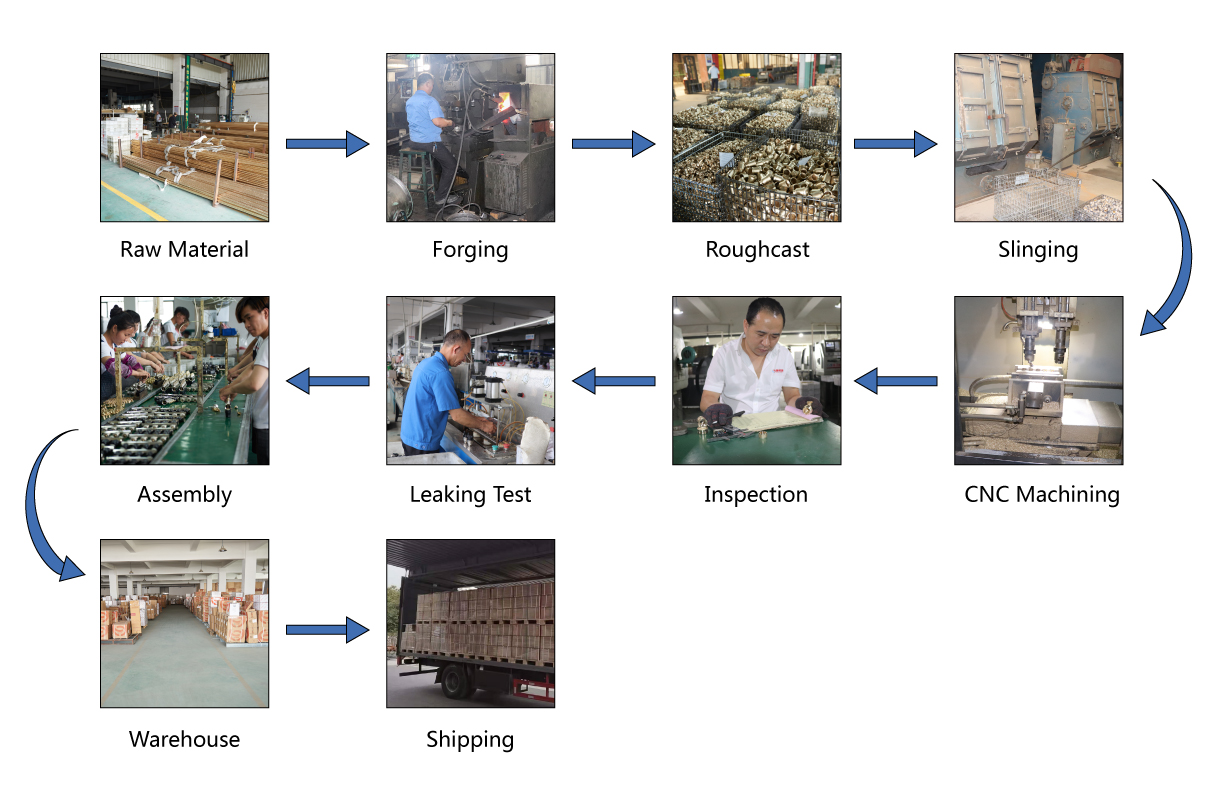

Processing Steps

Raw Material, Forging,Roughcast,Slinging, CNC Machining,Inspection,Leaking Test, Assembly,Warehouse,Shipping

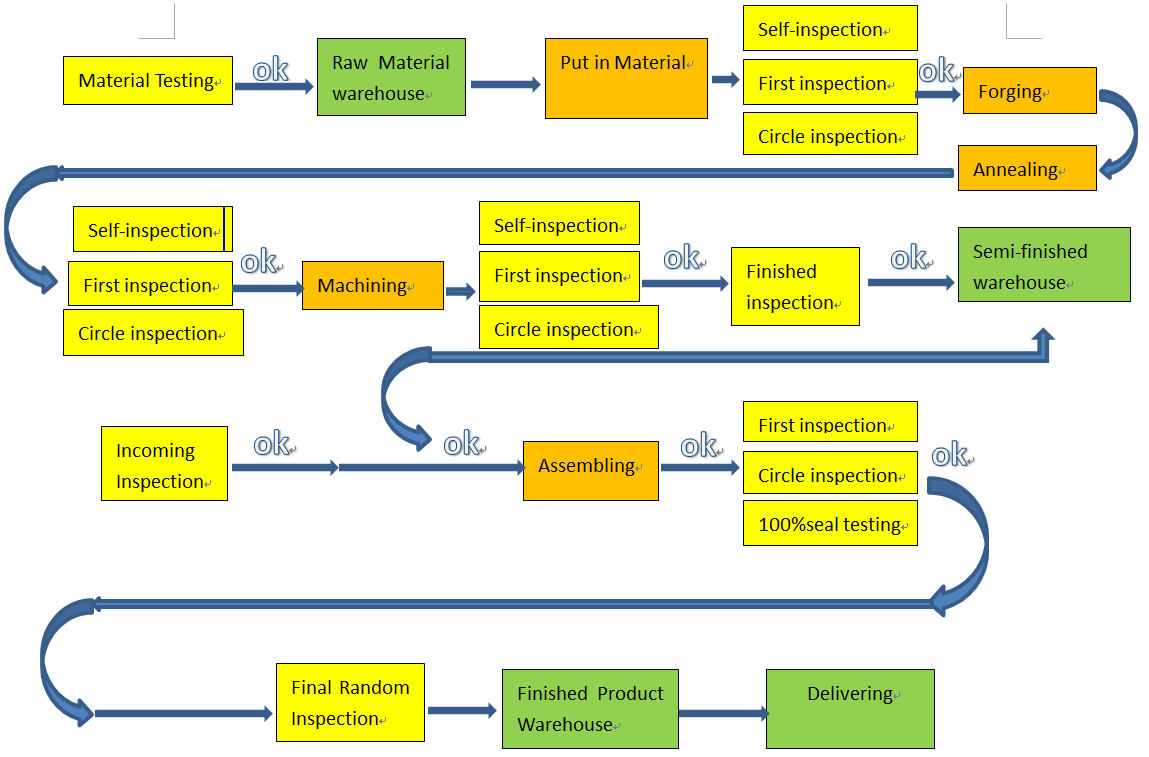

Material Testing,Raw Material Warehouse,Put In Material,Self-Inspection,First Inspection,Circle Inspection,Forging,Annealing,Self-Inspection,First Inspection,Circle Inspection,Machining, Self-Inspection,First Inspection,Circle Inspection,Finished Inspection,Semi-Finished Warehouse, Assembling,First Inspection,Circle Inspection,100% Seal Testing,Final Random Inspection, Finished Product Warehouse,Delivering

Applications

The pressure reducing valve is a valve that reduces the inlet pressure to a certain required outlet pressure through adjustment, and relies on the energy of the medium itself to automatically maintain a stable outlet pressure. From the point of view of fluid mechanics, the pressure reducing valve is a throttling element whose local resistance can be changed, that is, by changing the throttling area, the flow rate and the kinetic energy of the fluid are changed, resulting in different pressure losses, so as to achieve the purpose of pressure reduction. Then rely on the adjustment of the control and regulation system to balance the fluctuation of the pressure behind the valve with the spring force, so that the pressure behind the valve remains constant within a certain error range.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

1.Purpose and scope

A pressure reducer is designed to lower the pressure in drinking andindustrial water supply systems.The reducer maintains a constant predetermined outlet pressure (with the possibility of adjustment) in dynamic and static modes, regardless of changes in inlet pressure.

2.Principle of operation

Once in the inlet chamber, water acts with equal force on the valve (13) and on the lower surface of the piston.The spring elasticity force keeps the valve open until the water pressure in the outlet chamber acting on the upper plate of the piston is equal to the adjustment one. At this point, the valve begins to block the passage between the chambers, increasing local resistance and lowering the outlet pressure to a predetermined level.

Using the adjusting sleeve, the gearbox can be tuned to the required output pressure, which is different from the factory setting.

3.Gear setting

All gearboxes are factory set for an outlet pressure of 3 bar.The gearbox can be adjusted without dismantling.Before setting up the gearbox installed in the system, it is recommended that you open the maximum possible number of valves to remove air from the gearbox.The gearbox is adjusted at zero flow,

i.e. all the water taps of the system must be closed. A calibrated pressure

gauge should be installed on the pipeline section from the gearbox to the stopcock using a special tee OR boss.If all the taps are closed, the pressure gauge displays the outlet pressure at zero flow.

—To change the setting:

—- unscrew the protective cap;

—- Turn the adjusting sleeve with a screwdriver to set the required pressure. Clockwise rotation of the sleeve

leads to an increase in adjusting pressure, counterclockwise to its decrease.

— after adjustment, replace the protective cap.