High-Quality Press Release Valves from Trusted Manufacturers

When I think about optimizing performance in industrial applications, the Press Release Valve stands out as an essential component. I’ve often faced challenges when sourcing reliable parts, and I can confidently say that high-quality valves from reputable manufacturers make all the difference. These valves not only ensure safety but also enhance operational efficiency. I’ve found that working with established manufacturers guarantees durability and superior functionality, which are crucial for my projects. The design of the Press Release Valve allows for precise control, making it suitable for various applications. Plus, the materials used in their construction resist wear and tear, ensuring long-lasting performance. It's key for anyone in the industry to prioritize quality when making purchasing decisions. I encourage my peers to consider high-quality options that not only meet specifications but also exceed expectations. Trust me, investing in the right Press Release Valve can pay off in the long run, providing peace of mind and reliability in every use.

Press Release Valve Products Pioneers in the Field

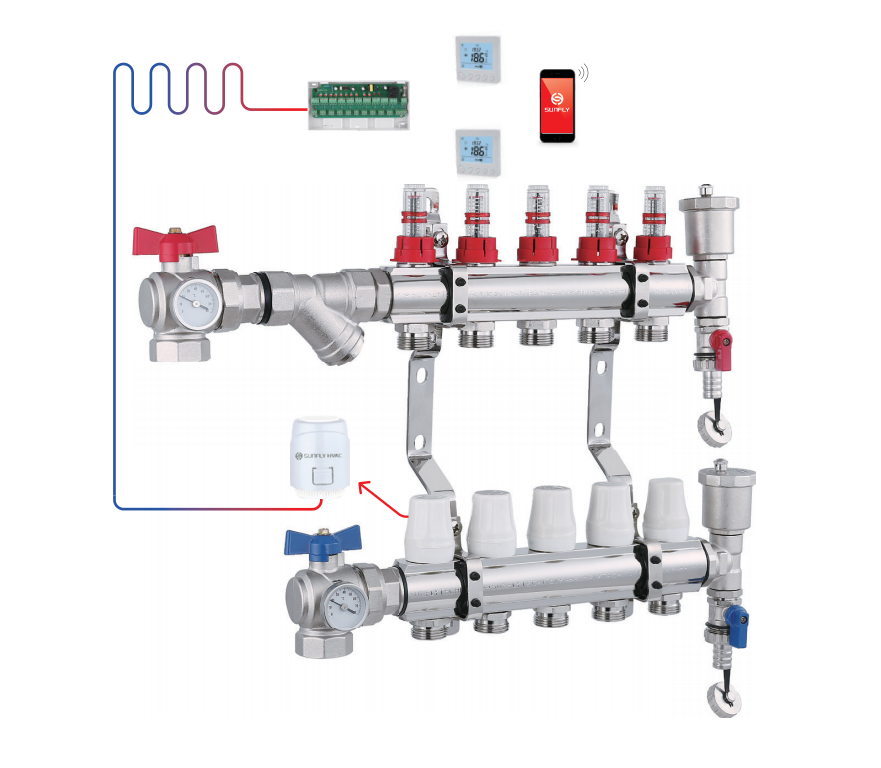

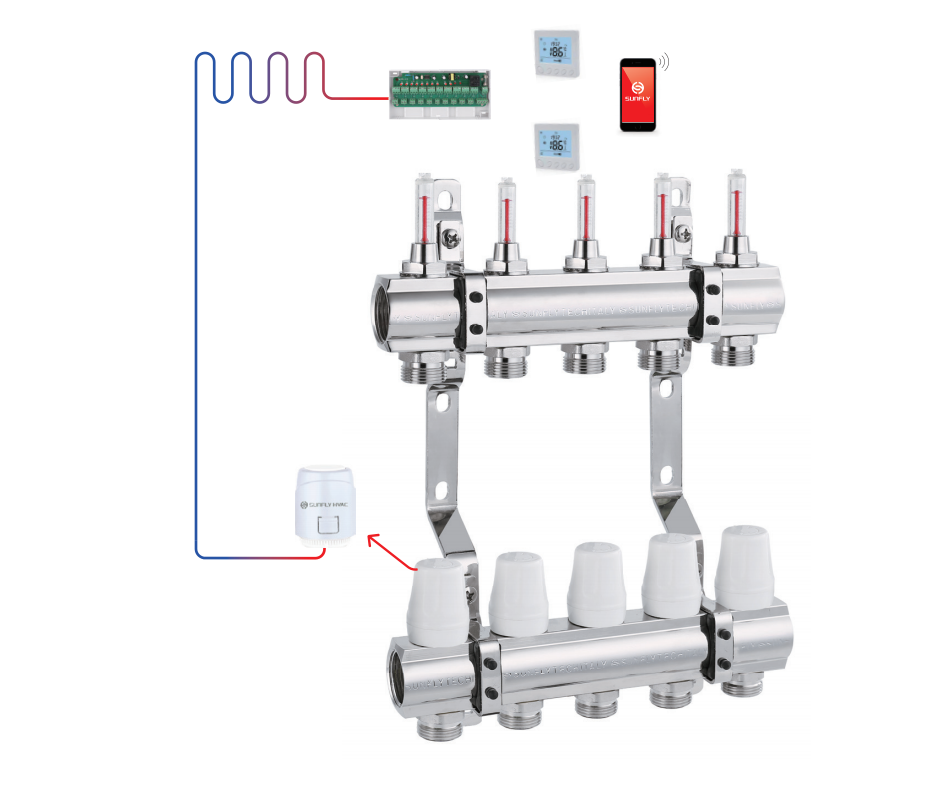

In the realm of HVAC solutions, innovation and reliability are paramount. As the industry increasingly gravitates towards intelligent control technologies, recent advancements in valve products have set new benchmarks for performance and efficiency. The introduction of cutting-edge valve designs not only enhances energy conservation but also significantly improves system responsiveness, catering to the evolving needs of global markets. These pioneering valve products stand out due to their incorporation of smart technology, enabling seamless integration with existing HVAC systems. This intelligent linkage supports enhanced monitoring and control, allowing users to optimize their operations effortlessly. Furthermore, the commitment to quality and precision ensures long-lasting durability, reducing maintenance costs and downtime, a vital consideration for procurement professionals. As the climate crisis intensifies and the demand for sustainable solutions escalates, these valve innovations offer a powerful response to global challenges. They empower businesses worldwide to adopt more energy-efficient practices, fostering an environmentally-friendly approach while simultaneously achieving economic benefits. Embracing such advanced technology positions organizations at the forefront of the HVAC industry, ready to meet the challenges of modern infrastructure with confidence and agility.

Press Release: Valve Products Pioneers in the Field

| Product Type | Material | Size | Operating Pressure (psi) | Temperature Range (°C) | Applications |

|---|---|---|---|---|---|

| Ball Valve | Stainless Steel | 1 inch | 150 | -20 to 120 | Water, Oil, Gas |

| Gate Valve | Brass | 2 inch | 250 | -10 to 130 | Water, Steam |

| Check Valve | Plastic | 3 inch | 75 | 0 to 80 | Pump Protection |

| Butterfly Valve | Ductile Iron | 4 inch | 100 | -20 to 100 | HVAC, Water Treatment |

| Solenoid Valve | Aluminum | 1/4 inch | 120 | 0 to 50 | Automated Systems |

Related Products