pressure reducing valve

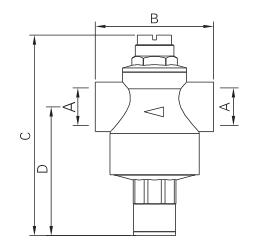

| Warranty: | 2 Years | Model Number | XF80833 |

| After-sale Service: | Online technical support | Type: | Automatic valve |

| Brass Project Solution Capability: | graphic design,3D model design,total

solution forProjects,CrossCategories Consolidation |

Keywords: | Safety valve |

| Application: | boiler,pressure vessel and pipeline | Color: | Nickel plated |

| Design Style: | Modern | Size: | 1/2” 3/4” |

| Place of Origin: | Zhejiang, China | MOQ: | 200 pcs |

| Brand Name: | SUNFLY | ||

| Product name: | Brass safety valve | ||

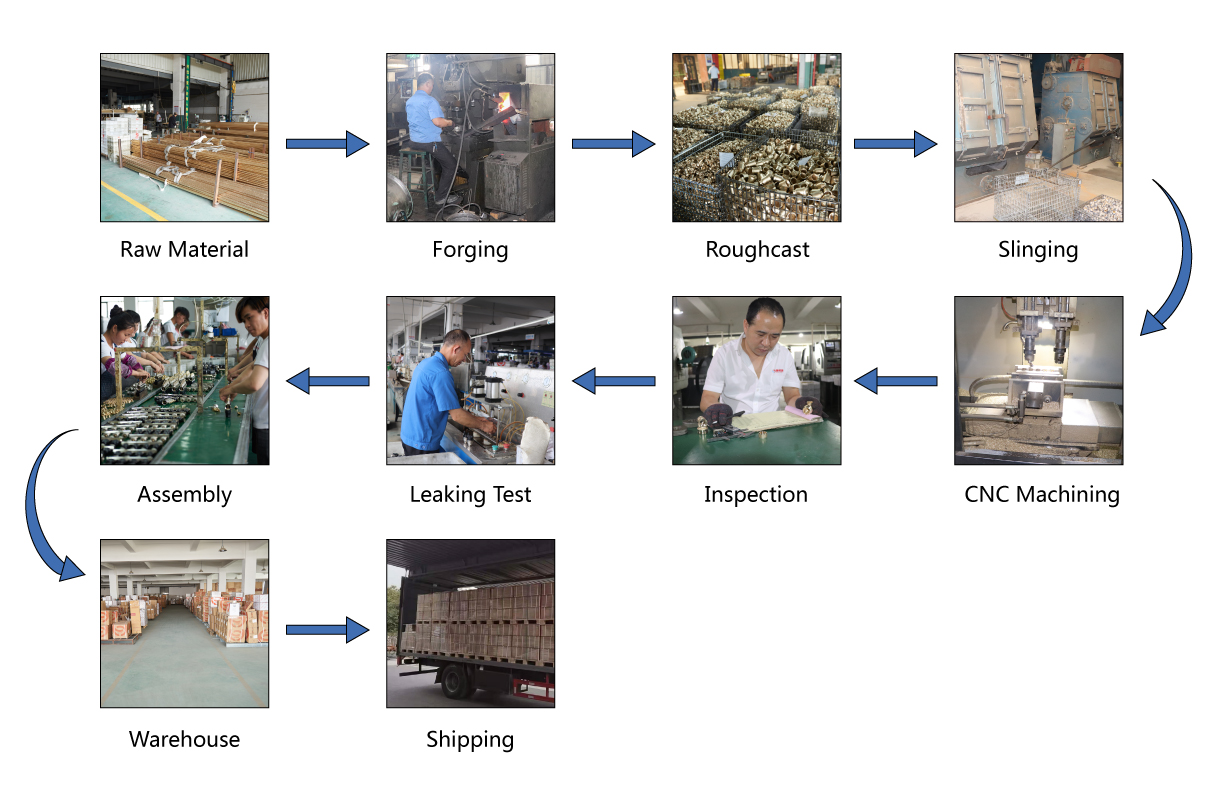

Processing Steps

Raw Material, Forging, Roughcast, Slinging, CNC Machining, Inspection, Leaking Test, Assembly, Warehouse, Shipping.

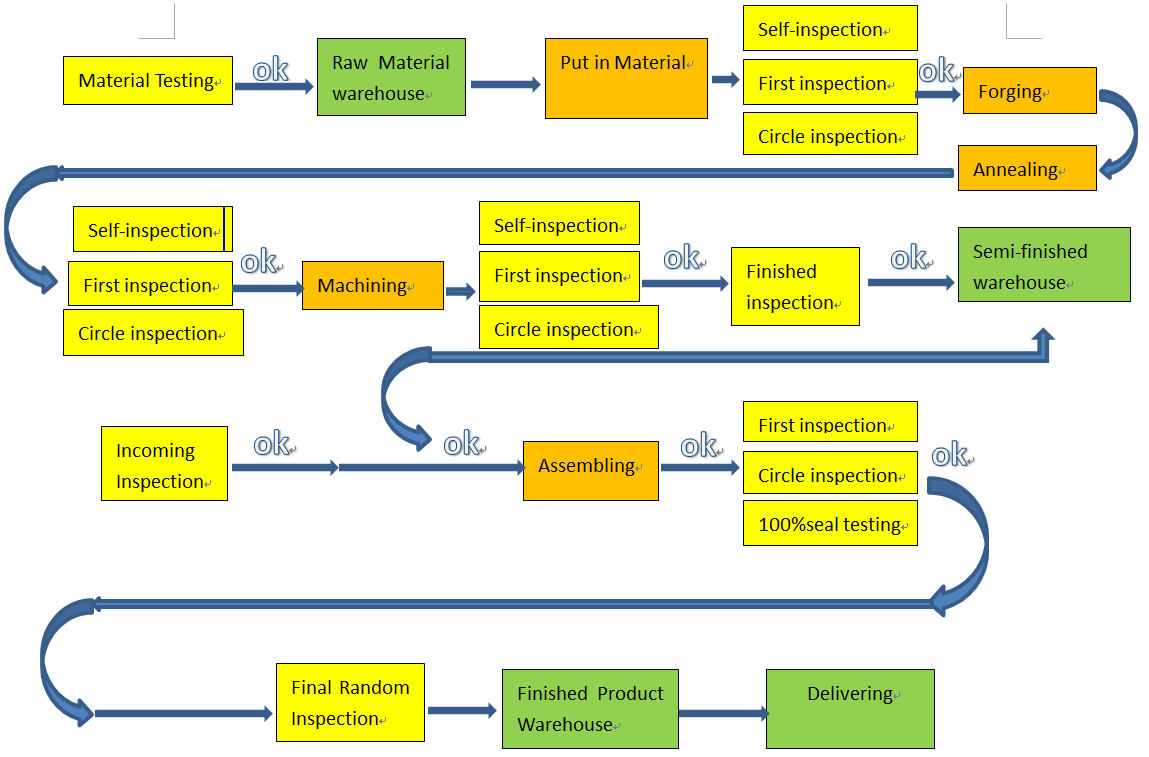

Material Testing,Raw Material Warehouse,Put In Material,Self-Inspection,First Inspection,Circle Inspection,Forging,Annealing,Self-Inspection,First Inspection,Circle Inspection,Machining, Self-Inspection,First Inspection,Circle Inspection,Finished Inspection,Semi-Finished Warehouse, Assembling,First Inspection,Circle Inspection,100% Seal Testing,Final Random Inspection, Finished Product Warehouse,Delivering

Applications

The pressure reducing valve is a valve that reduces the inlet pressure to a certain required outlet pressure through adjustment,and relies on the energy of the medium itself to automatically maintain a stable outlet pressure. From the point of view of fluid mechanics, the pressure reducing valve is a throttling element whose local resistance can be changed,that is,by changing the throttling area, the flow rate and the kinetic energy of the fluid are changed, resulting in different pressure losses, so as to achieve the purpose of pressure reduction. Then rely on the adjustment of the control and regulation system to balance the fluctuation of the pressure behind the valve with the spring force, so that the pressure behind the valve remains constant within a certain error range.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Product Description

1. Purpose and scope

A pressure reducer is designed to lower the pressure in drinking andindustrial water supply systems.

The reducer maintains a constant predetermined outlet pressure (with the possibility of adjustment) in dynamic and static modes, regardless of changes in inlet pressure.

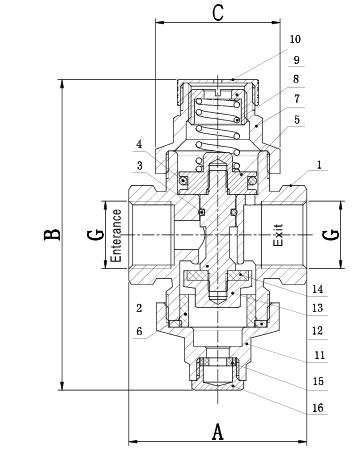

2. Design and materials used

1.housing

2.piston

3.small sealing ring

4.o-ring large

5.Tareka piston

6.casing cover gasket

7.case cover

8.spring

9.adjusting sleeve

10.protective cap

11.cork

12.cork gasket

13.valve

14.valve gasket

The gear case (1), cover (7), cap (10) and plug (11) are made of high-quality brass CW 617N (according to uropean standard EN 12165) by beating, forging and turning with nickel plating of external surfaces.A movable piston (2) is located in the housing, on the same axis with which a valve (13) is fixed. These parts and the adjusting sleeve (9) are made of the same brass by turning.

The spring (8) is made of AISI 304 stainless steel. Valve gaskets (14) and plugs (12), small (3) and large (4) o-rings are made of wear-resistant NBR rubber.

SUNFLY ® reserves the right to make changes in the design that do not lead to a deterioration of the technical parameters of the product.