Top China Manufacturer of Ball Valve with Drain – Quality & Value

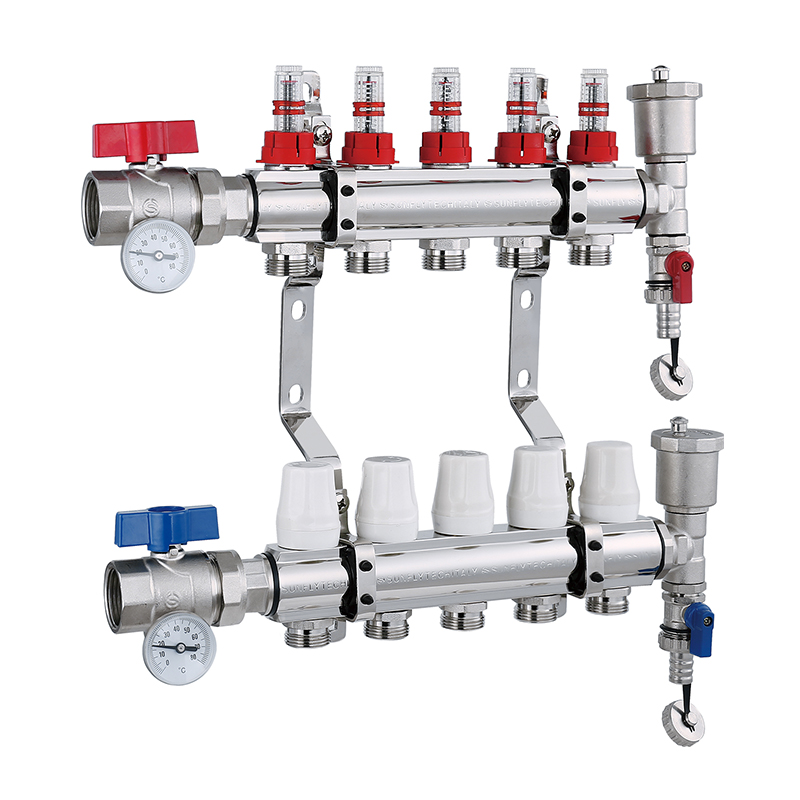

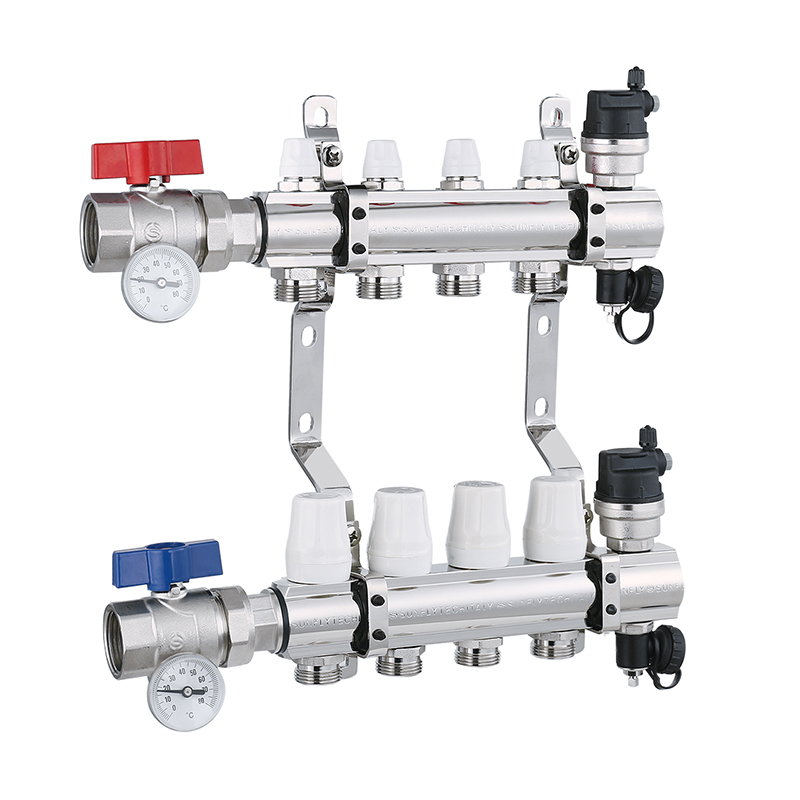

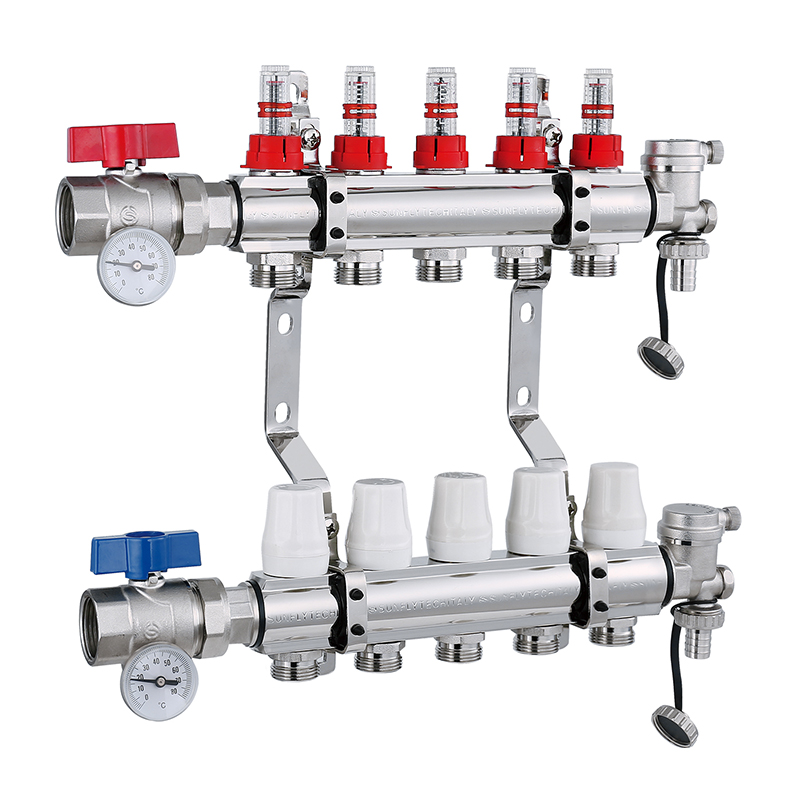

When I first began searching for a reliable ball valve with drain, I quickly realized the importance of quality and durability. These valves are perfect for various industrial applications, especially when dealing with draining processes. Sourced from trusted manufacturers in China, these ball valves ensure impeccable performance and longevity. I appreciate how these valves are designed with easy operation in mind, allowing for seamless maintenance and efficiency in any system. The drain feature is particularly beneficial for quick and effortless liquid removal. Every detail matters, and I trust that these products have been crafted with precision to meet the high standards required in B2B transactions. If you're like me and prioritize quality when sourcing ball valves, you’ll be glad to explore options from leading Chinese manufacturers who understand the market’s needs. Embrace these reliable solutions and enhance your operations with our premium ball valve with drain today!

Ball Valve With Drain in 2025 Your End-to-End Solution

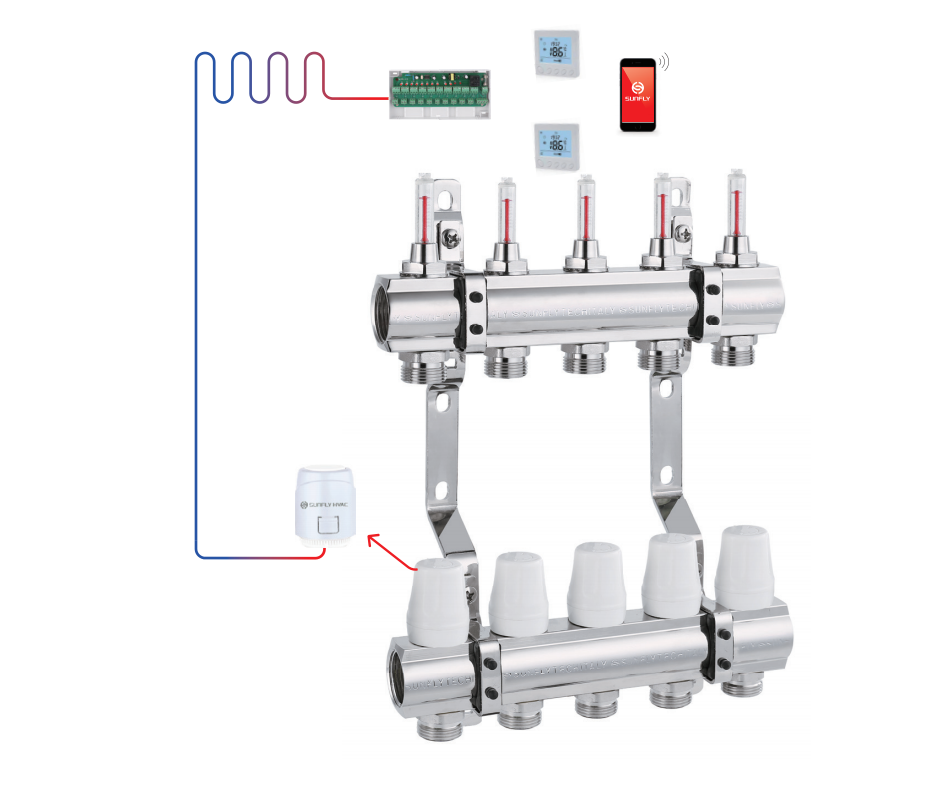

In 2025, the demand for advanced and efficient solutions in industrial applications is at an all-time high. Among innovative options, ball valves with drain functionality are leading the charge, offering ease of maintenance and increased operational efficiency. These valves not only provide reliable flow control but are designed to facilitate drainage and cleaning processes, minimizing downtime and enhancing productivity. Their robust construction ensures durability even in the most demanding environments, making them a must-have for global procurement buyers seeking quality and performance. As industries evolve, the integration of intelligent control systems is becoming essential. These systems enhance the functionality of ball valves, enabling users to monitor and manage fluid flow remotely. By leveraging data analytics and automation, businesses can optimize their operations, reduce waste, and improve decision-making processes. In an era where sustainability and efficiency are paramount, investing in such technology will significantly impact an organization’s bottom line. By choosing ball valves with drain capabilities as part of a comprehensive end-to-end solution, companies can ensure seamless operations while aligning with the future of industrial practices. Embracing innovation not only strengthens operational resilience but also positions organizations to meet the challenges of tomorrow’s marketplace, ensuring a competitive edge in a rapidly evolving landscape.

Ball Valve With Drain in 2025 Your End-to-End Solution

| Feature | Description | Benefit | Applications |

|---|---|---|---|

| Material | Stainless Steel | Corrosion resistant and durable | Oil & Gas, Water Treatment |

| Size Range | 1/2" to 12" | Versatile sizing options for different applications | Industrial, Commercial |

| End Connection | Flanged, Threaded | Easy integration with existing systems | Pipelines, Equipment |

| Operating Pressure | Up to 150 PSI | Reliable performance under pressure | Process Control, HVAC |

| Temperature Range | -20°C to 200°C | Suitable for a wide range of environments | Chemical Processing, Power Generation |

Related Products