Reliable Temperature Safety Valve Manufacturer in China

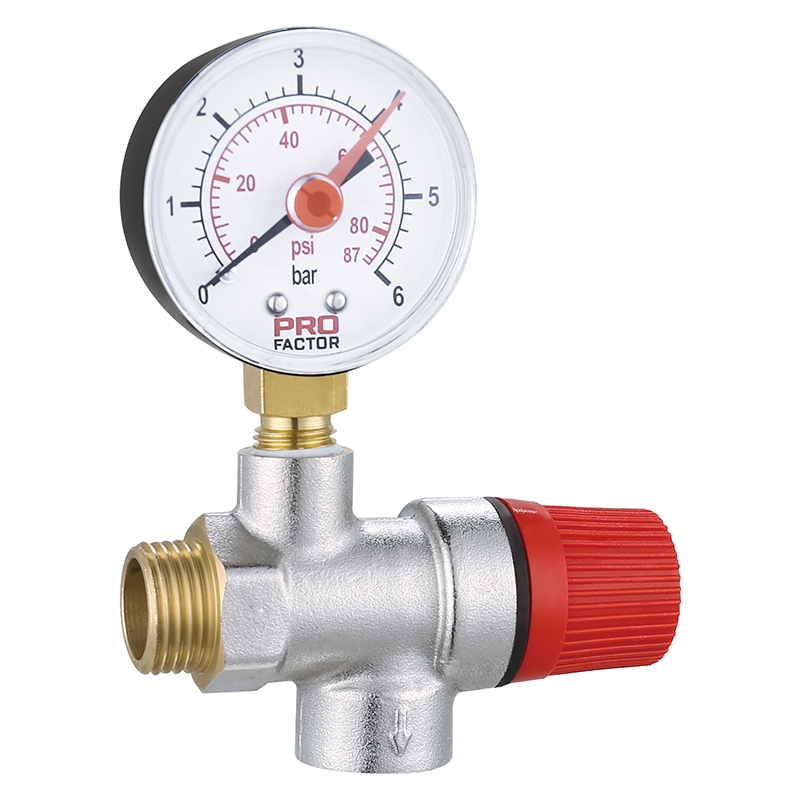

As a trusted source for high-quality Temperature Safety Valves, I understand the critical role these components play in ensuring safe operations in various industrial applications. Our valves, sourced from reliable manufacturers in China, are designed to automatically relieve excess pressure to prevent equipment failure and maintain safety standards. With precision engineering and durable materials, these Temperature Safety Valves stand up to demanding environments, ensuring safety and efficiency. I’m proud to say that my products are rigorously tested and meet international quality certifications, giving you peace of mind when making your purchase. Whether you’re in the energy, manufacturing, or processing industry, finding the right valve is essential. I’m here to assist you in selecting the perfect solution tailored to your specific needs. Reach out today, and let’s enhance your operations together!

Temperature Safety Valve Application Guarantees Peak Performance

In the world of HVAC systems, ensuring optimal performance while maintaining safety standards is paramount. Temperature safety valves play a critical role in this equation, acting as the first line of defense against overheating and system failure. By automatically releasing excess pressure or steam when temperatures exceed safe limits, these valves guarantee not only the integrity of equipment but also the safety of operations. This is especially crucial in environments where precision and reliability are non-negotiable. Integrating advanced temperature safety valve technology into HVAC systems allows for enhanced control and monitoring in real-time. This results in improved energy efficiency and reduced downtime, benefiting operational costs and performance outcomes. For global buyers looking for innovative solutions to meet stringent regulatory requirements and improve system reliability, investing in quality temperature safety valves is a step towards achieving peak performance across different applications. Selecting the right temperature safety valve requires careful consideration of factors such as the operating environment, system requirements, and compatibility with existing infrastructure. As demand for energy-efficient and safe solutions grows worldwide, understanding the importance of these components can help purchasing managers make informed decisions that lead to successful project outcomes.

Temperature Safety Valve Application Guarantees Peak Performance

| Application | Temperature Range (°C) | Pressure Rating (bar) | Material | Certifications |

|---|---|---|---|---|

| Steam Systems | -10 to 180 | 16 | Stainless Steel | ISO 9001 |

| Chemical Processing | 0 to 150 | 20 | Carbon Steel | ASME |

| Power Generation | -20 to 200 | 25 | Alloy Steel | PED |

| Food & Beverage | -5 to 100 | 10 | 304 Stainless Steel | FDA |

Related Products