3 Ways Valve: Top OEM Suppliers for Quality Solutions

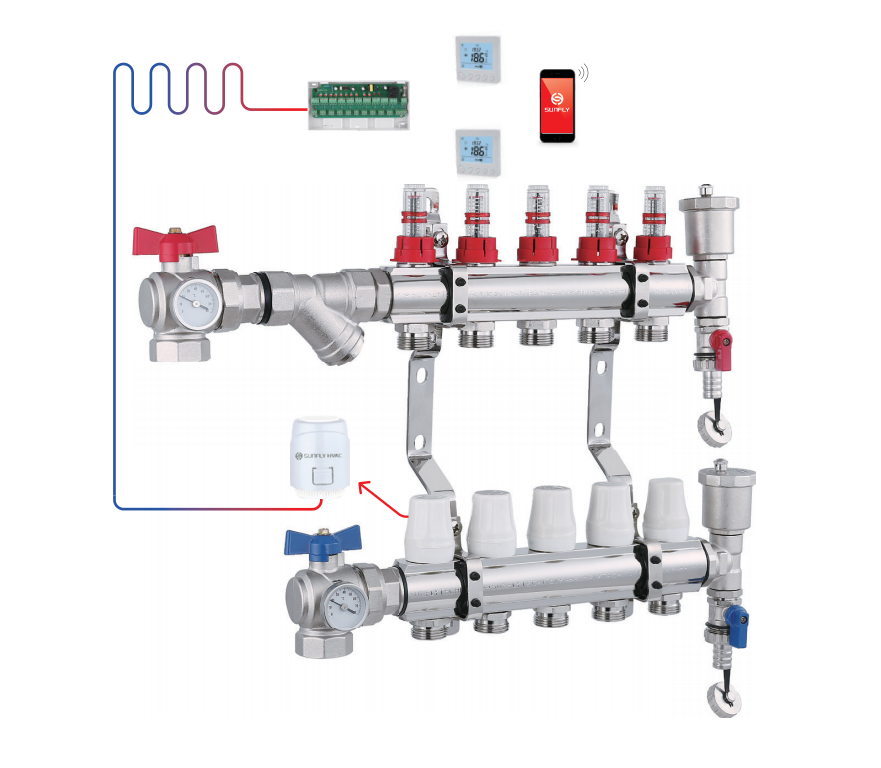

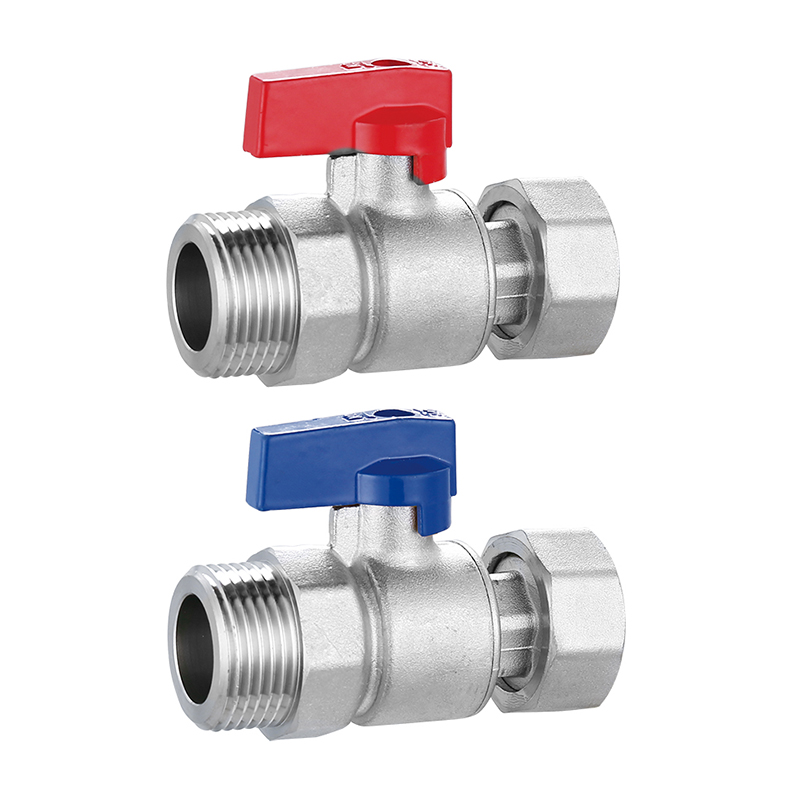

When it comes to optimizing valve performance, I have found that there are 3 ways valve solutions can significantly enhance operations for OEMs and suppliers alike. Firstly, choosing the right valve materials can improve durability and resistance to wear, ensuring long-term efficiency. Secondly, implementing advanced automation features can streamline processes and reduce manual errors, making every step smoother. Lastly, regular maintenance guidelines are key to prolonging the lifespan of your valves, ultimately saving costs down the road. For B2B purchasers seeking reliable partnerships, my focus is on providing tailored solutions that fit your unique needs, backed by years of industry expertise. I understand the dynamics of OEM and supplier relationships, which is why I prioritize quality and reliability in every valve I offer. Together, we can elevate your operations and drive success in your projects.

3 Ways Valve Supplier Factory-Direct Excellence

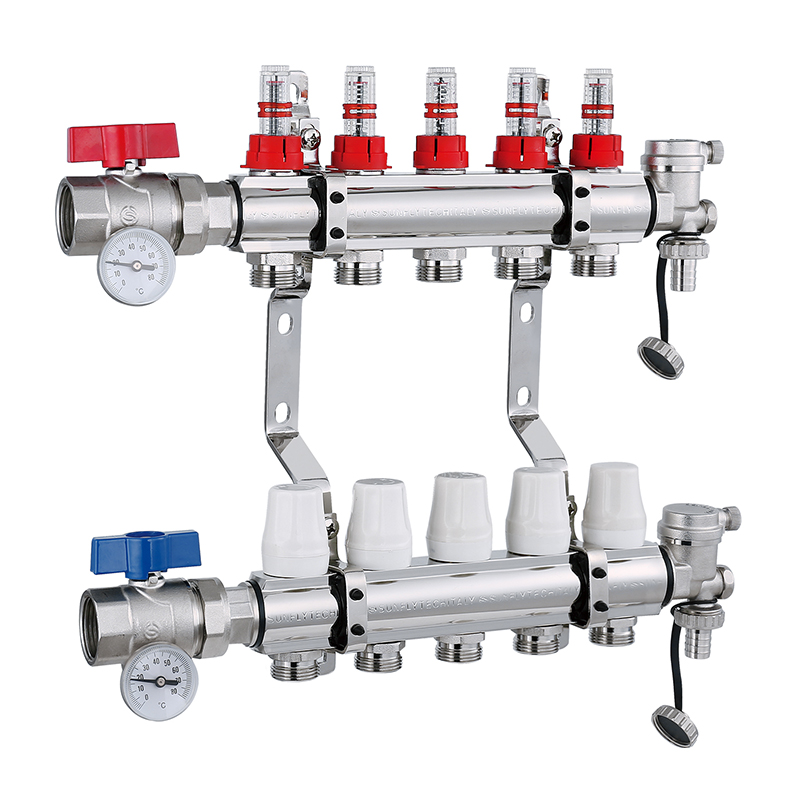

In the competitive landscape of the HVAC industry, sourcing high-quality valves directly from manufacturers can significantly enhance operational efficiency and product reliability. Partnering with a valve supplier that prioritizes factory-direct excellence offers numerous advantages that global buyers should consider. Here are three compelling reasons why this approach can be beneficial for procurement professionals. First, purchasing valves directly from the manufacturer eliminates unnecessary middlemen, leading to reduced costs. This streamlined supply chain means that buyers can obtain high-quality products at more competitive prices. Additionally, factory-direct purchasing ensures that you benefit from the latest innovations and technologies, as manufacturers are often on the cutting edge of industry advancements. This direct line to the source allows for better negotiations regarding price and terms, ensuring that your procurement strategy not only meets quality expectations but also remains budget-friendly. Second, working directly with a valve manufacturer fosters stronger collaboration and communication. Buyers can engage closely with the production team, gaining valuable insights into product specifications and customization options. This relationship enhances transparency, allowing for smoother processes and quicker resolution of any potential issues. As a result, global buyers can ensure that their specific requirements are met, and they can expect timely deliveries that align with their project timelines. Lastly, a focus on factory-direct excellence often indicates a commitment to quality control and sustainable manufacturing practices. When sourcing valves from a manufacturer, buyers can ensure that stringent quality checks are in place, translating to increased reliability and performance. Furthermore, many manufacturers are adopting eco-friendly practices to minimize environmental impact, offering procurement professionals an opportunity to align their purchasing decisions with sustainability goals. This holistic approach not only serves operational needs but also enhances brand reputation and responsibility on a global scale.

3 Ways Valve Supplier Factory-Direct Excellence

| Dimension | Performance Indicator | Value |

|---|---|---|

| Lead Time | Average Delivery Time | 5-7 Days |

| Quality Assurance | Defect Rate | < 1% |

| Customer Support | Response Time | Within 24 Hours |

| Product Range | Variety of Valves | > 50 Types |

| Sustainability | Eco-Friendly Practices | 100% Compliance |

Related Products