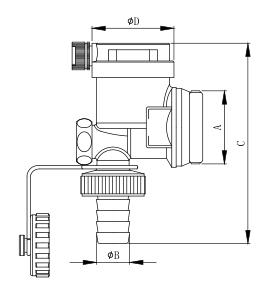

Brass air vent valve

Product Details

| Warranty: | 2 Years | Number: | XF90970 |

| After-sale Service: | Online technical support | Type: | Floor Heating Systems |

| Style: | Modern | Keywords: | Air vent valve |

| Brand Name: | SUNFLY | Color: | Nickel plated |

| Application: | Apartment Design | Size: | 1/2’’ 3/8’’ 3/4’’ |

| Name: | Brass radiator valve | MOQ: | 200 pcs |

| Place of Origin: | Zhejiang, China | ||

| Brass Project Solution Capability: | Graphic design, 3D model design, total solution for Projects, Cross Categories Consolidation | ||

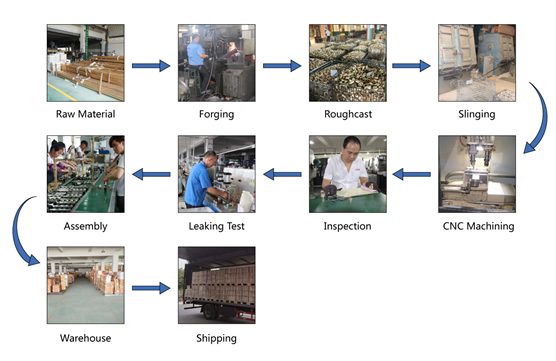

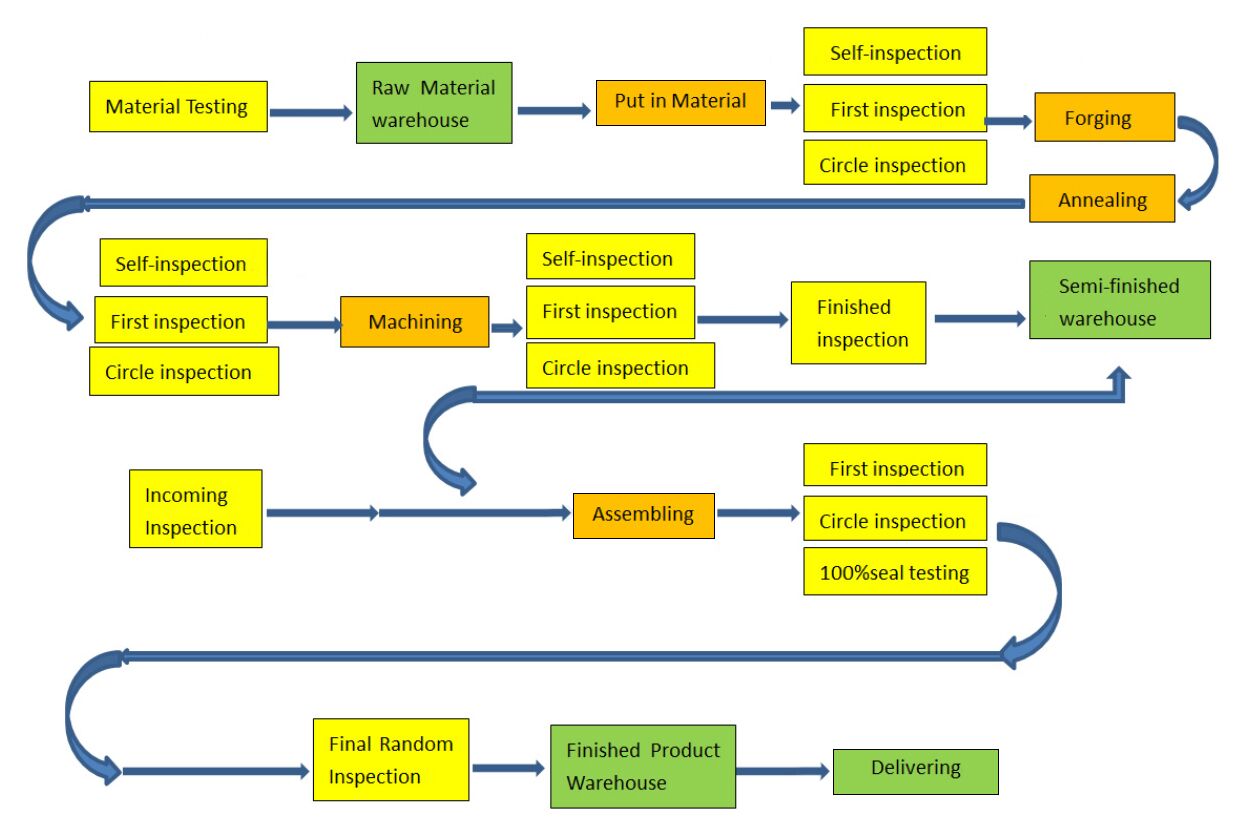

Processing Steps

Raw Material, Forging,Roughcast,Slinging, CNC Machining,Inspection,Leaking Test, Assembly,Warehouse,Shipping

Material Testing, Raw Material Warehouse, Put In Material, Self-Inspection, First Inspection, Circle Inspection, Forging, Annealing, Self-Inspection, First Inspection, Circle Inspection, Machining, Self-Inspection, First Inspection, Circle Inspection, Finished Inspection, Semi-Finished Warehouse, Assembling, First Inspection, Circle Inspection, 100% Seal Testing, Final Random Inspection, Finished Product Warehouse, Delivering

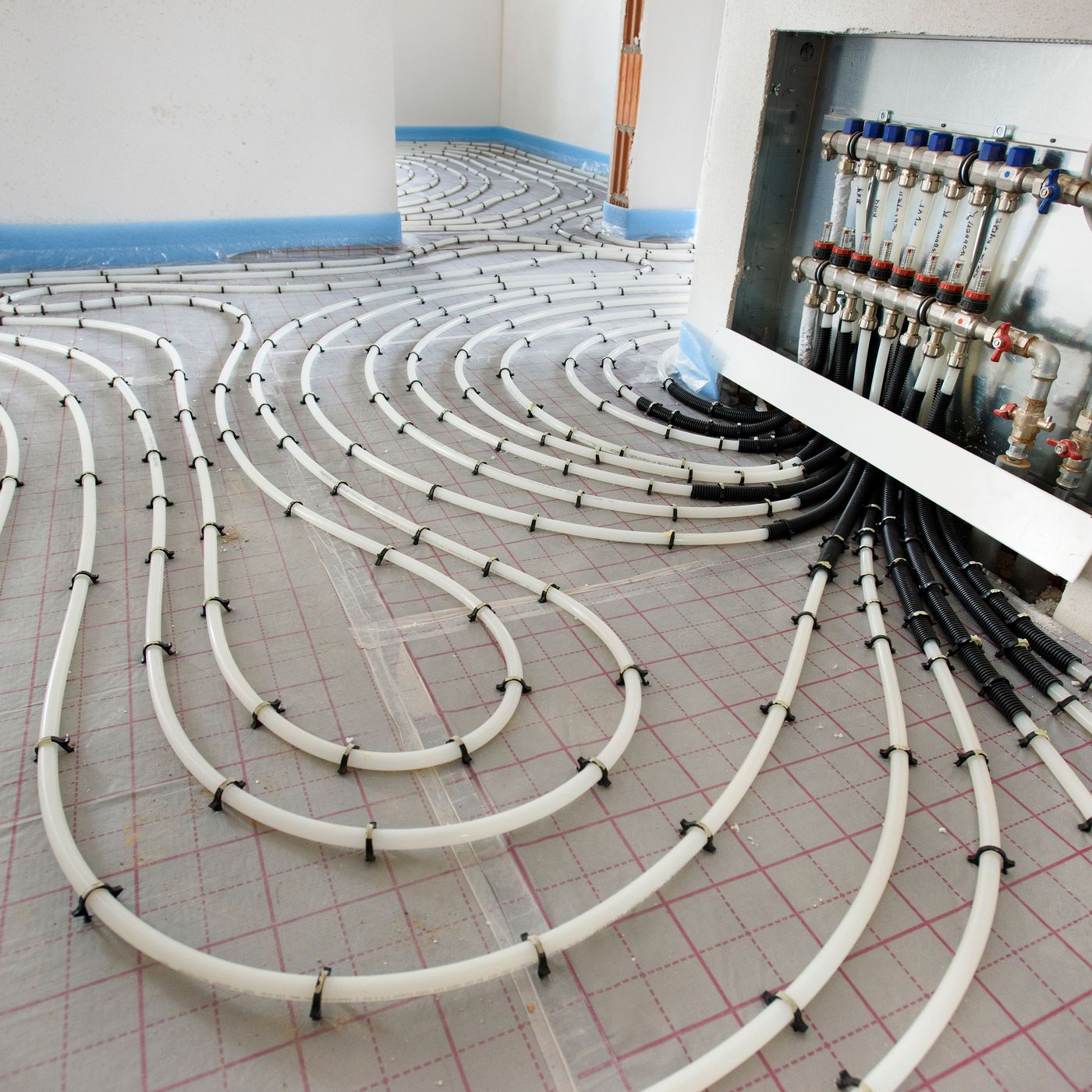

Applications

Air vent are used in independent heating systems, central heating systems, heating boilers, central air conditioning, floor heating and solar heating systems and other pipeline exhaust.

Main Export Markets

Europe,East-Europe,Russia,Middle-Asia,North America,South America and so on.

Installation instructions:

The device is delivered to the consumer completely ready for use and does not require additional adjustment.

Before installing the air vent, the pipeline must be cleaned of rust, dirt, scale, sand and other foreign particles that affect the performance of the device. Heating,internal cold and hot ater supply systems, boiler pipelines at the end of their installation must be flushed with water until it comes out without mechanical suspensions .

The air vent must be installed in a vertical position with the protective cap up (with connection on a cylindrical pipe thread according ) in places where air and gas can accumulate (the highest points of piping systems, air collectors, boilers, collectors, heating devices).

The air vent should not experience external loads: vibration, uneven tightening of fasteners . It is allowed to install an air vent without a shut-off valve - if there are shut-off valves nearby on the pipeline and there are no other strict system requirements.It is not allowed to carry out hydraulic tests of the system with installed air vents or with shutoff valves open in front of them. No load on the protective cap is permitted.

The air vent must be securely fixed to the pipeline, leakage of the working fluid through the threaded part is unacceptable. Threaded connections should be made using FUM tape (PTFE-polytetrafluoroethylene, fluoroplastic sealing material), polyamide yarn with silicone or linen as winding sealing material. In this case,it is necessary to ensure that excess of this material does not fall on the shut-off valve seat. This may cause the valve to become inoperative. Check for proper installation.

After installation, a manometric system leak test should be performed. This test allows you to protect the system from leaks and damage associated with them.To bring the air vent into operation, it is necessary to unscrew a little (without removing) the protective cap located at the top of the cover.