OEM Hot and Cold Mixing Valve Supplier for Optimal Temperature Control

As a dedicated supplier of hot and cold mixing valves, I understand the critical role these components play in various industrial applications. Our OEM hot and cold mixing valves are designed to offer superior performance and reliability, ensuring optimal temperature control in your systems. Whether you’re in manufacturing, construction, or plumbing, our products meet stringent quality standards and can be customized to fit your specific needs. I've seen firsthand how our valves improve efficiency and consistency in operations, helping you achieve better outcomes. With a focus on durability and ease of installation, these mixing valves minimize downtime and maintenance costs. When you choose our hot and cold mixing valves, you are not just buying a component; you are investing in a solution that supports your business's success. Let’s connect and explore how we can provide you with the best mixing valves tailored to your requirements.

Hot And Cold Mixing Valve Now Trending Custom Solutions,

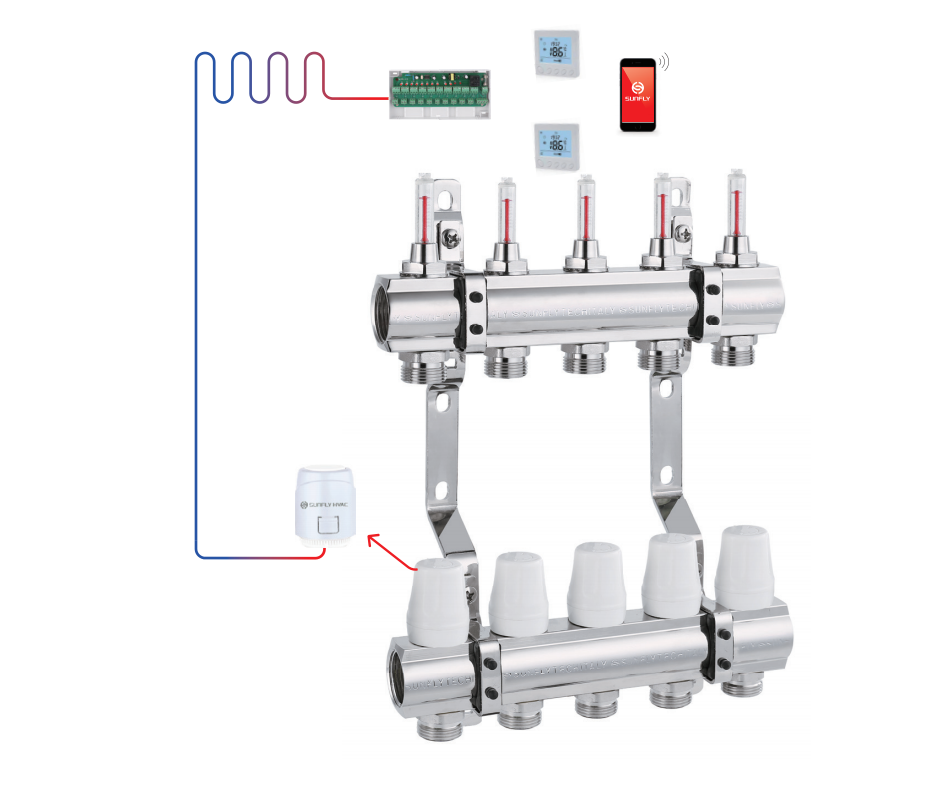

In today's rapidly evolving market, the demand for efficient and customizable heating, ventilation, and air conditioning (HVAC) solutions has never been greater. One of the standout products that has gained significant attention is the hot and cold mixing valve. This innovative device not only optimizes energy consumption but also provides precise temperature control, making it a sought-after solution for various applications across industries. The trend toward customized solutions underscores the importance of understanding specific client needs. Procurement professionals are increasingly looking for partners who can offer tailored designs and configurations that align with their operational requirements. Whether for residential, commercial, or industrial settings, these mixing valves can be engineered to handle diverse fluid types and varying pressure conditions, ensuring reliability and efficiency in temperature management. As global buyers navigate this landscape, prioritizing quality, expertise, and innovation is critical. Effective collaboration with manufacturers that understand the nuances of HVAC systems and can deliver bespoke mixing valves will empower businesses to enhance their systems, reduce costs, and improve overall performance. Embracing this trend not only positions companies for success in their operations but also contributes to a more sustainable future.

Hot And Cold Mixing Valve Now Trending Custom Solutions

| Feature | Description | Application | Material | Customization Options |

|---|---|---|---|---|

| Temperature Control | Automatically adjusts the temperature by mixing hot and cold water. | Residential, Commercial | Brass, Stainless Steel | Custom sizing, finish options |

| Flow Rate Control | Regulates the flow of water for optimal usage. | Shower systems, Faucets | Plastic, Copper | Flow rate specifications |

| Safety Features | Includes anti-scald technology to prevent burns. | Medical, Industrial | Silicone, Polymer | Pressure settings |

| Design Flexibility | Compact and versatile designs to fit various installations. | Residential, Retail | Aluminum, Composite | Color, Texture customizations |

| Energy Efficiency | Reduces energy consumption through effective mixing. | Eco-friendly homes, Offices | Recycled materials, Eco-friendly finishes | Energy ratings |

Related Products