Customized Ball Valve Manufacturer in China - Quality & Precision

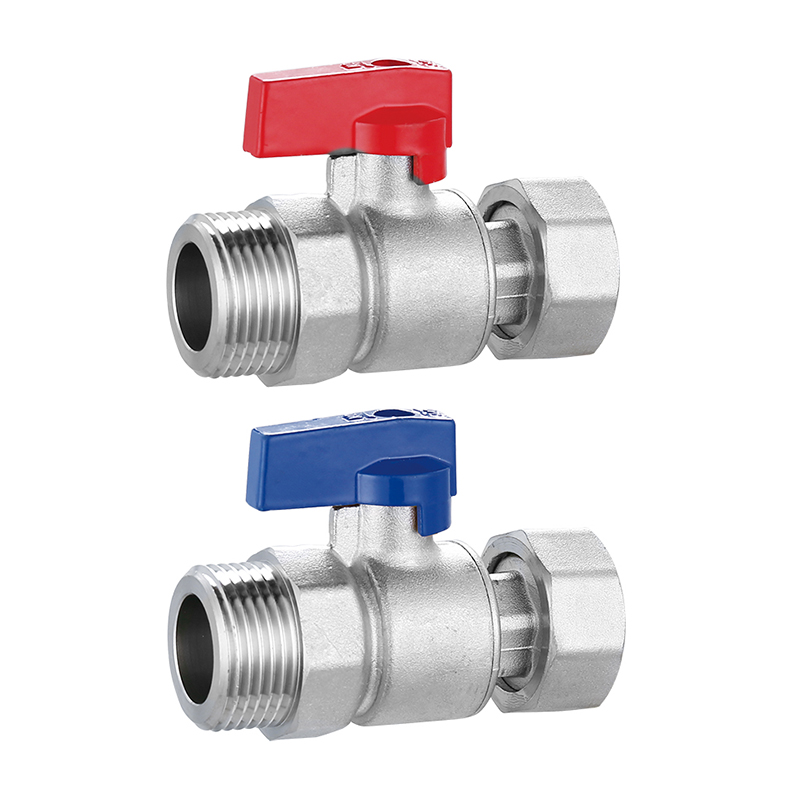

When I think about reliability in fluid control, I immediately consider customized ball valves. Sourced directly from trusted manufacturers in China, these valves can be tailored to meet the precise needs of your applications. Whether you require specific sizes, materials, or special features, I can help you find the perfect fit for your project. What I love most about these customized solutions is their ability to enhance efficiency while ensuring safety in operation. With a focus on durability and performance, these ball valves are designed to withstand the pressures of diverse environments. And since I work closely with reputable manufacturers in China, I can assure you of the highest quality standards. If you're seeking customized ball valves that deliver on both performance and value, let's connect. I’m here to guide you through the selection process, ensuring you make an informed decision that aligns with your business needs.

Customized Ball Valve Leads the Global Market Guarantees Peak Performance

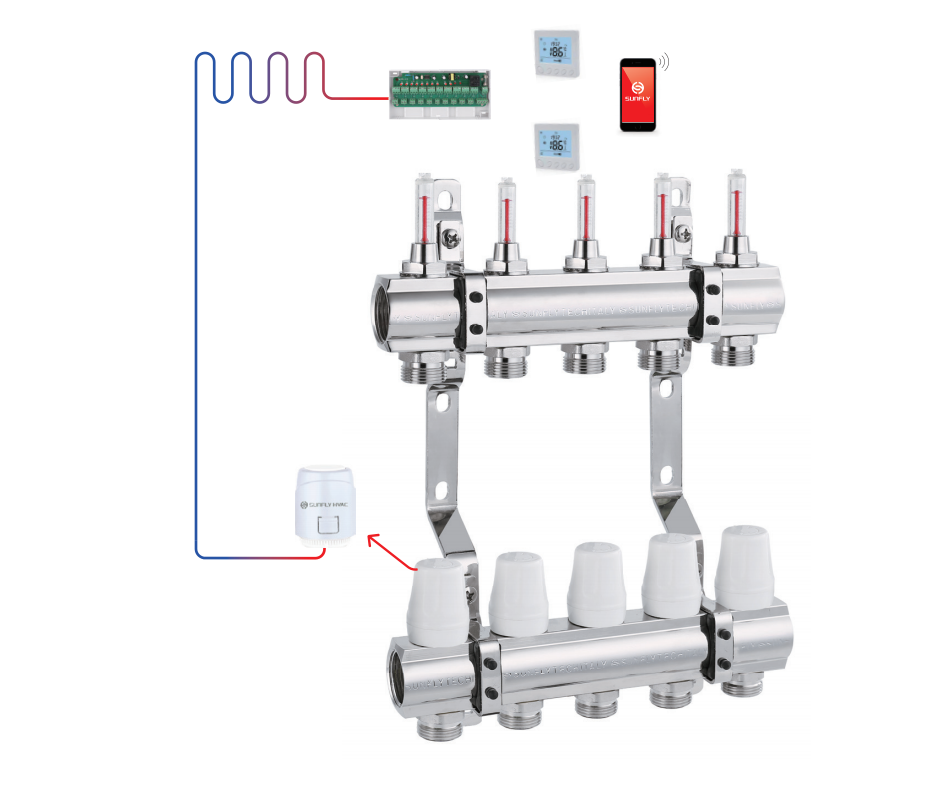

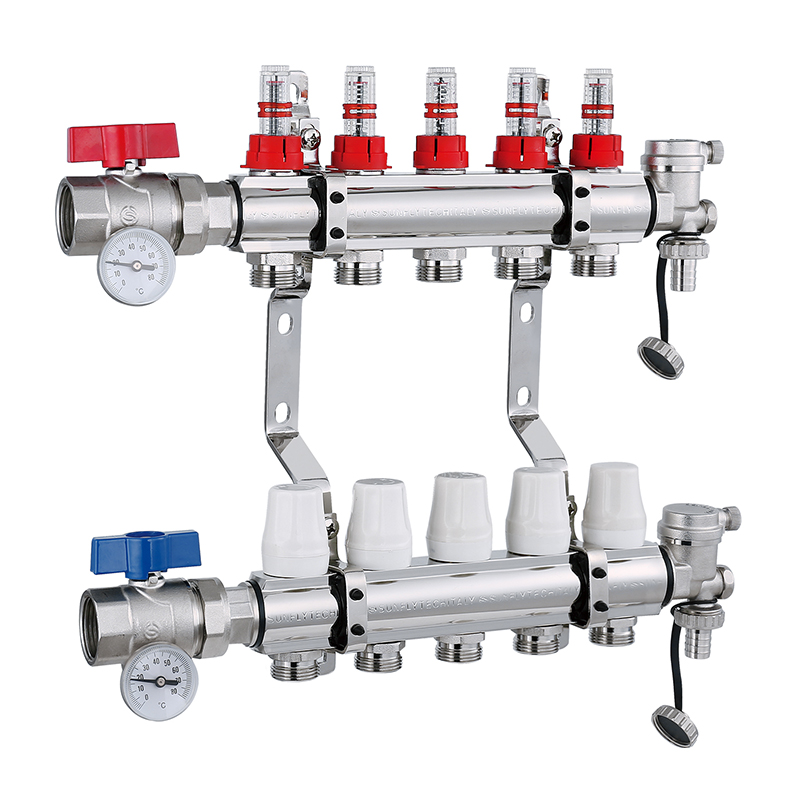

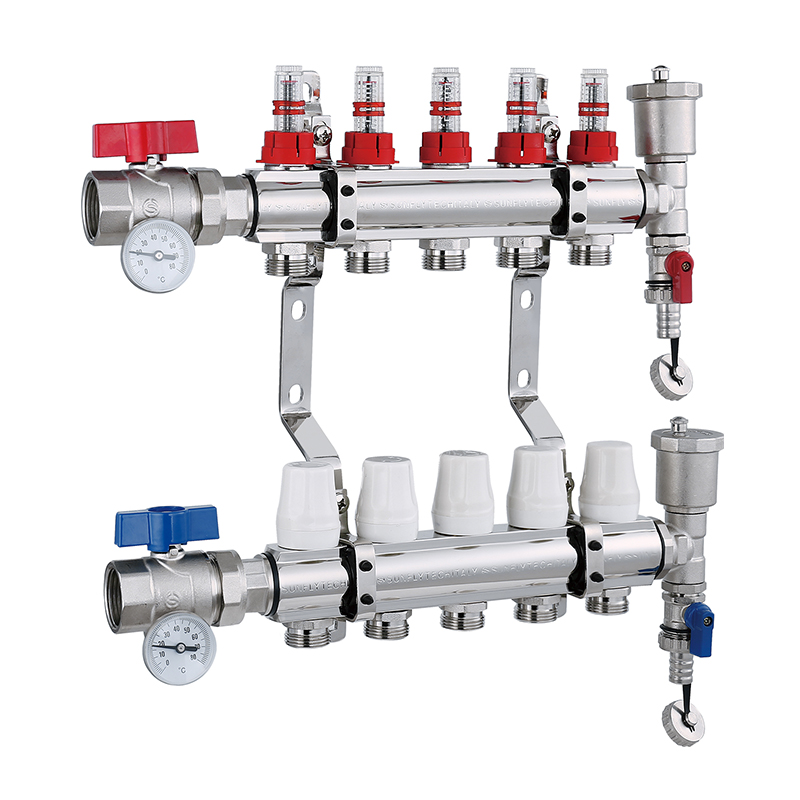

In today's industrial landscape, the demand for custom solutions is on the rise, particularly in the realm of valve technology. Customized ball valves have emerged as a crucial component for achieving optimal performance across various applications. With the capability to cater to unique specifications and operational requirements, these valves not only enhance efficiency but also ensure longevity and reliability in fluid and gas control systems. This adaptation to specific needs is vital for industries ranging from HVAC to chemical processing, positioning customized ball valves as a sought-after choice among global buyers. The technological advancements in manufacturing processes have enabled the production of high-quality customized ball valves that meet stringent industry standards. By leveraging sophisticated materials and innovative designs, these valves provide exceptional performance, reducing the risk of leaks and failures. Moreover, incorporating smart control features allows for better monitoring and operational adjustments, which are essential for maintaining peak efficiency in dynamic environments. As industries globally strive for sustainability and cost-effectiveness, the demand for these high-performance valves is bound to grow. Investing in customized ball valves represents a strategic decision for businesses aiming to enhance their operational capabilities. As global procurement expands, the focus is increasingly on sourcing components that not only fulfill immediate needs but also align with long-term goals of efficiency and sustainability. The adaptability and reliability of customized ball valves ensure they are leading the market while offering organizations the confidence to achieve their performance objectives.

Customized Ball Valve Leads the Global Market Guarantees Peak Performance

| Valve Type | Material | Size Range | Pressure Rating | Applications |

|---|---|---|---|---|

| Floating Ball Valve | Stainless Steel | 1/4" - 12" | 150 - 600 PSI | Oil & Gas, Water Supply |

| Trunnion Ball Valve | Carbon Steel | 2" - 48" | 300 - 1500 PSI | Power Plants, Chemical Processing |

| Full Port Ball Valve | PVC | 1/2" - 6" | 10 - 30 PSI | Water Treatment, Irrigation |

| V-Port Ball Valve | Alloy Steel | 1" - 8" | 150 - 300 PSI | Flow Control, HVAC |

Related Products