High-Quality Electromagnetic Valve from Leading Manufacturers

As a professional in the industrial sector, I understand the importance of reliable components in your operations. That's why I recommend investing in high-quality electromagnetic valves. These valves play a crucial role in controlling fluid flow, ensuring efficiency and performance in your systems. I’ve seen firsthand how partnering with reputable manufacturers can significantly impact your production processes. These manufacturers prioritize quality, durability, and precision, guaranteeing that the electromagnetic valves can handle the demands of various applications. When selecting a supplier, I always look for those with proven track records and a commitment to customer satisfaction. High-quality electromagnetic valves can lead to lower maintenance costs and increased productivity. Your manufacturing process deserves the best, and I’m confident that choosing the right components will help you achieve your business goals efficiently. Let’s elevate your operations with top-notch electromagnetic valves today!

Electromagnetic Valve Is The Best Custom Solutions,

In today's rapidly evolving industrial landscape, the demand for customized solutions has never been higher, particularly in the realm of electromagnetic valves. These components play a crucial role in various applications, including HVAC systems, industrial automation, and fluid control, ensuring efficiency and reliability. For global buyers seeking the best in custom solutions, understanding the intricacies of electromagnetic valves and the technology behind them is essential. Customized electromagnetic valves offer distinct advantages tailored to specific operational needs. By opting for bespoke solutions, businesses can enhance system performance, improve energy efficiency, and reduce operational downtime. The advanced manufacturing processes allow for the integration of cutting-edge technology, ensuring that each valve meets exact specifications. This results in durable, high-performance systems that can handle demanding environments, contributing to a seamless workflow and increased profitability. Investing in high-quality, customized electromagnetic valves not only streamlines operational efficiency but also positions businesses at the forefront of innovation. As industries continue to evolve, the role of advanced control systems will become increasingly vital. Therefore, collaborating with experts who understand the technology and can provide tailored solutions is imperative for driving future success in a competitive marketplace.

Electromagnetic Valve Is The Best Custom Solutions

| Valve Type | Application | Material | Pressure Rating | Temperature Range | Custom Options |

|---|---|---|---|---|---|

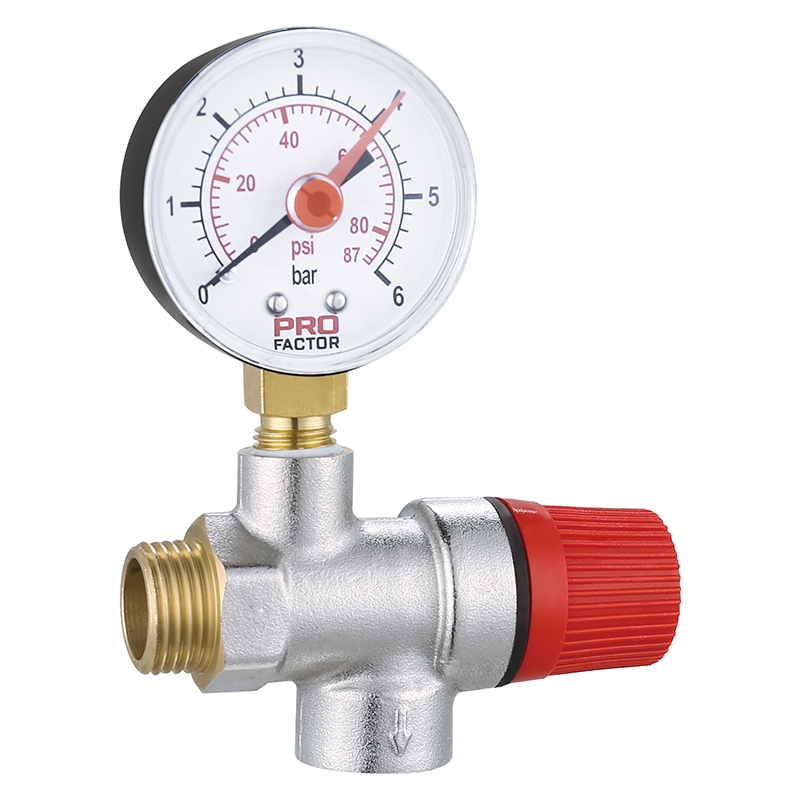

| 2/2 Way Solenoid Valve | Water Control | Brass | 0-10 bar | -10 to 80 °C | Yes |

| 3/2 Way Solenoid Valve | Air Applications | Aluminum | 0-8 bar | -20 to 60 °C | Yes |

| Industrial Solenoid Valve | Chemical Processing | Stainless Steel | 0-16 bar | -40 to 100 °C | Yes |

| Pilot Operated Valve | Hydraulic Systems | Plastic | 0-25 bar | -15 to 80 °C | Yes |

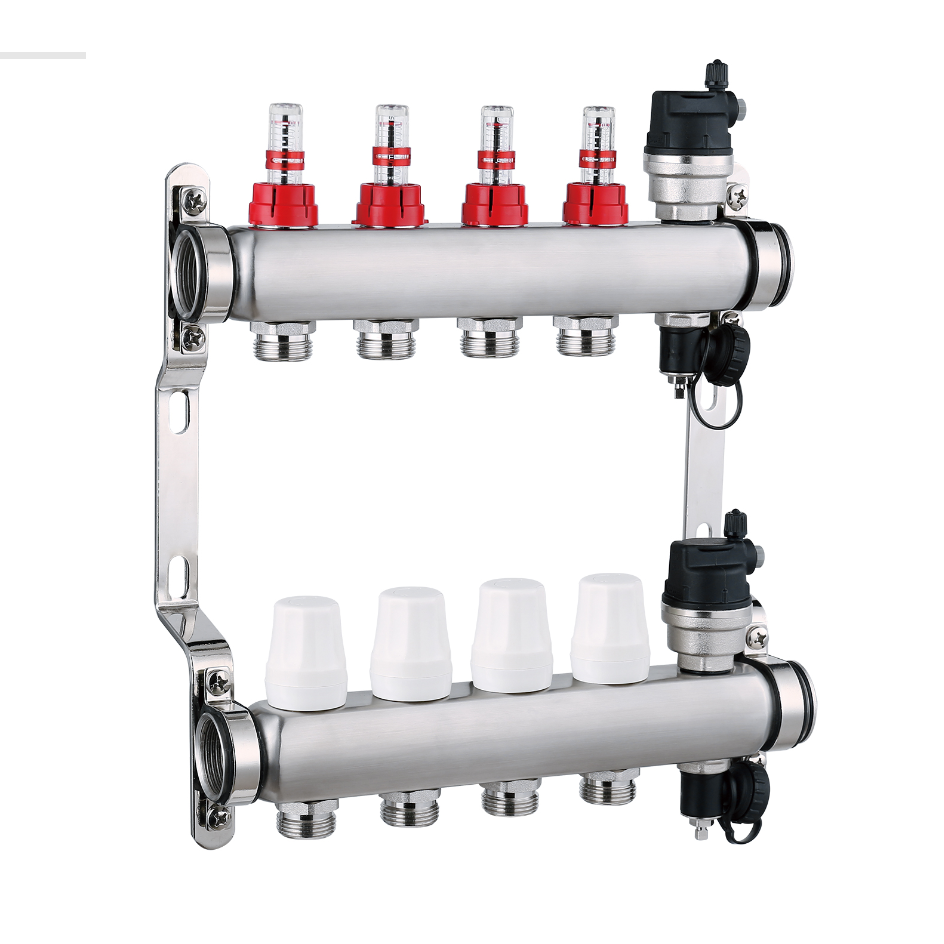

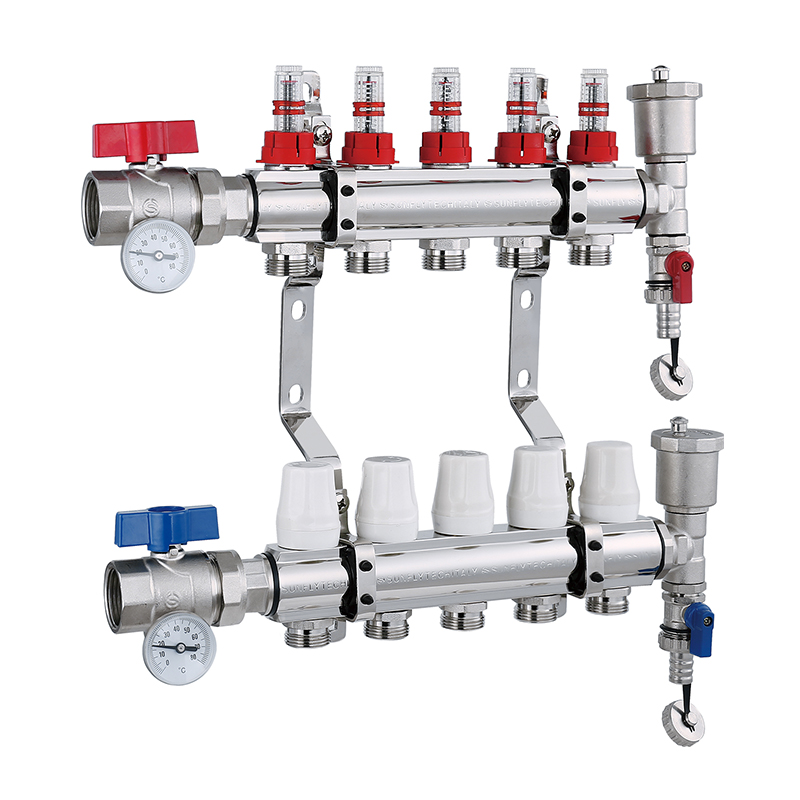

Related Products